¶ New Features & Enhancements

Compared with 2024.1 released on April 2024, here are the new features and enhancements provided in R2024.2 release:

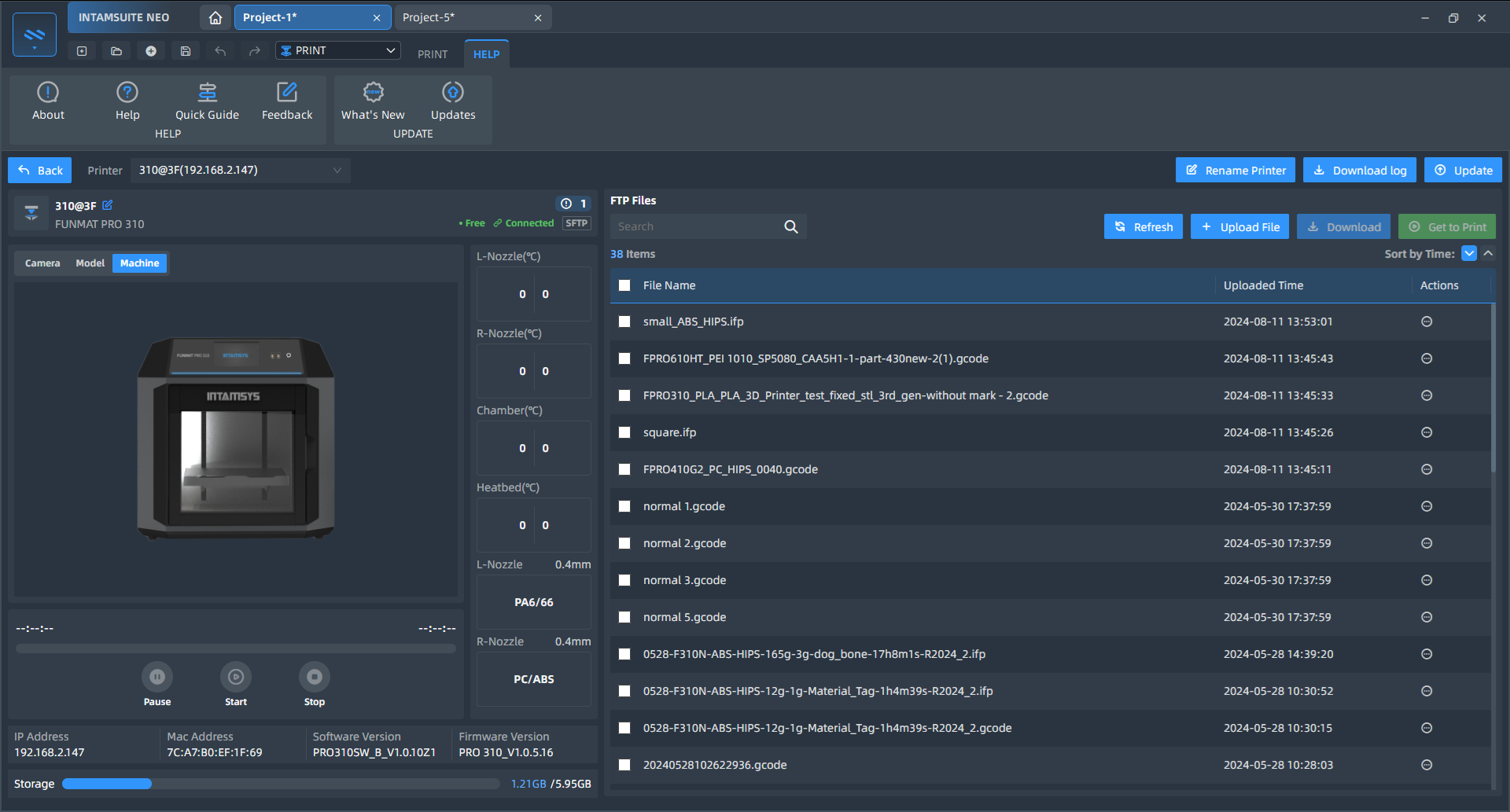

1. Improve the user experience of remote print module to make the process smoother than before. And also deliver the new features below -

- Remote print module extends to support FUNMAT PRO 410(with INTAMTOUCH PRO 410 V1.2.7.32 or newer version) and FUNMAT PRO 610HT, besides FUNMAT PRO 310.

- Please make sure INTAMTOUCH for the printer above upgrades to latest version.

- Select to download log files and print files.

- Support SFTP as file transfer protocol for all printers, safer than FTP.

- Upload multiple print files at a time, and can be canceled at any time.

- when uploading print file from current project, its default name is changed to the format of “[Date]-[Printer Type]-[Material1 Name]-[Material2 Name]-[Material1 Weight]-[Material2 Weight]-[File Name of First Inserted Model]-[Estimated Print Time]-[Current Version of INTAMSUITE NEO]”, e.g. “0528-F610HT-PEEK-SP5000-52g-18g-dog_bone-5h25m39s-R2024_2.gcode”.(PMS-2673)

- Upgrade software of INTAMTOUCH remotely (For FUNMAT PRO 310 only).

- The printer name can be updated and sychronized in both sides of INTAMTOUCH and remote print module (For FUNMAT PRO 310 only).

- Check the details of specified print file in almost real time.

- Any file in print file list can be deleted, and no longer limited to your own uploaded.

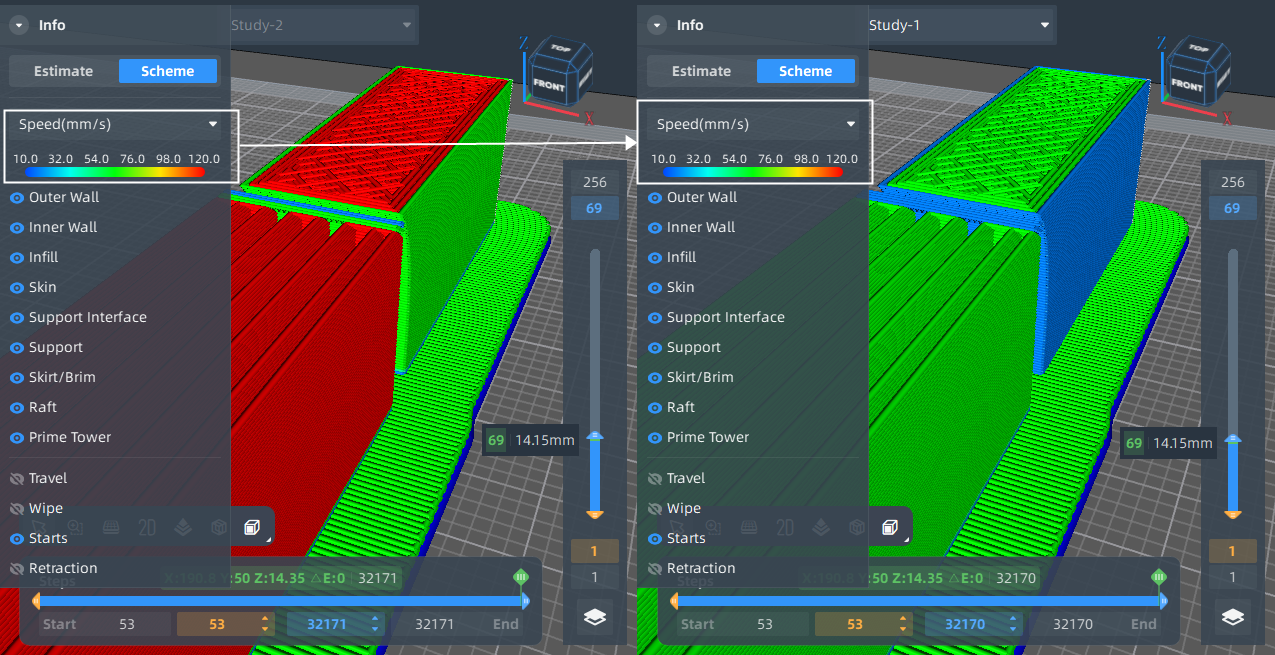

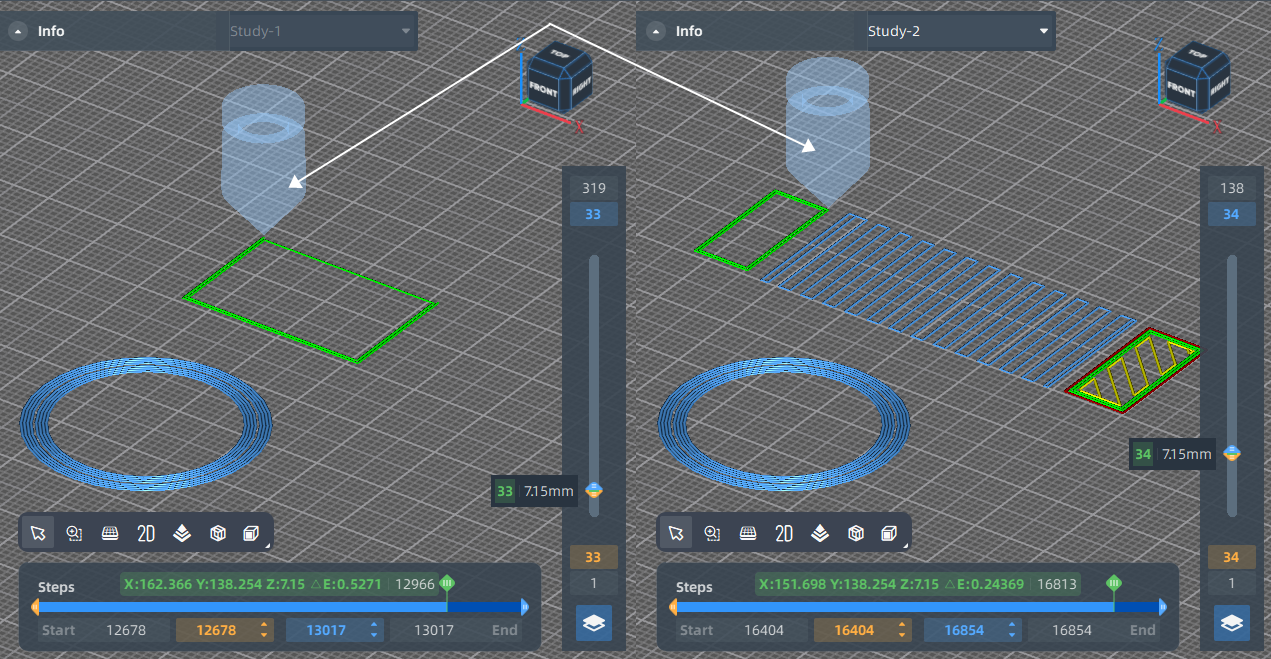

2. Synchronize the legend range (minimum and maximum value) in two windows with the same result type in Preview environment. In other words, the same color means the same value in left and right study result, so you can compare the results more effectively.

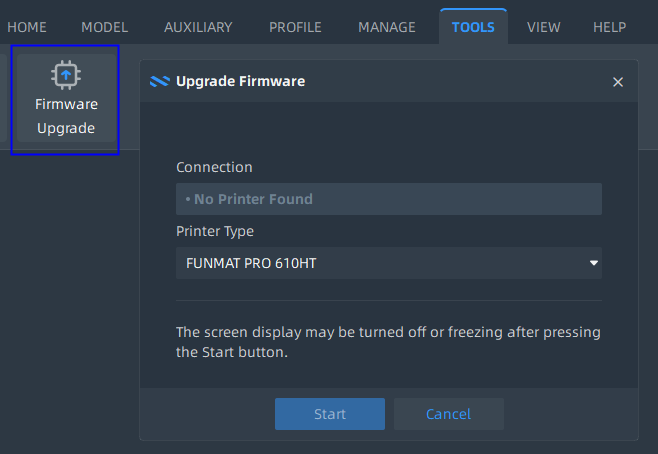

3. Upgrade firmware for all printer types (HT, 310, 410, 610HT) via USB cable in INTAMSUITE NEO.

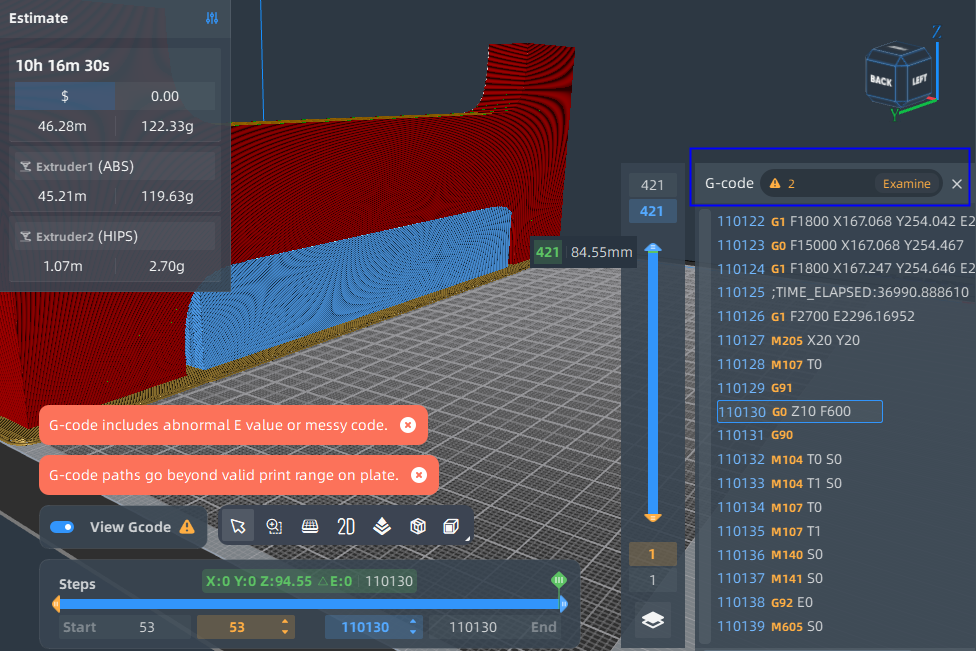

4. Basic diagnosis on Gcode is performed when entering Preview environment, including abnormal extrusion value, messy code and invalid print range etc. You can go through each possible error after seeing pop-up warning message.

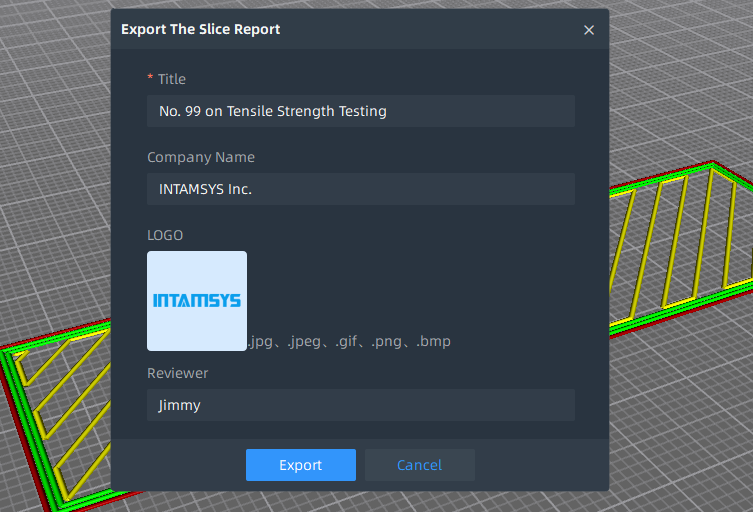

5. Export slicing report in preset format with basic information of the project, model, printer, material, profile and results etc. Please note it doesn't support the study with gcode imported since no any settings for slicing before can be retrieved.

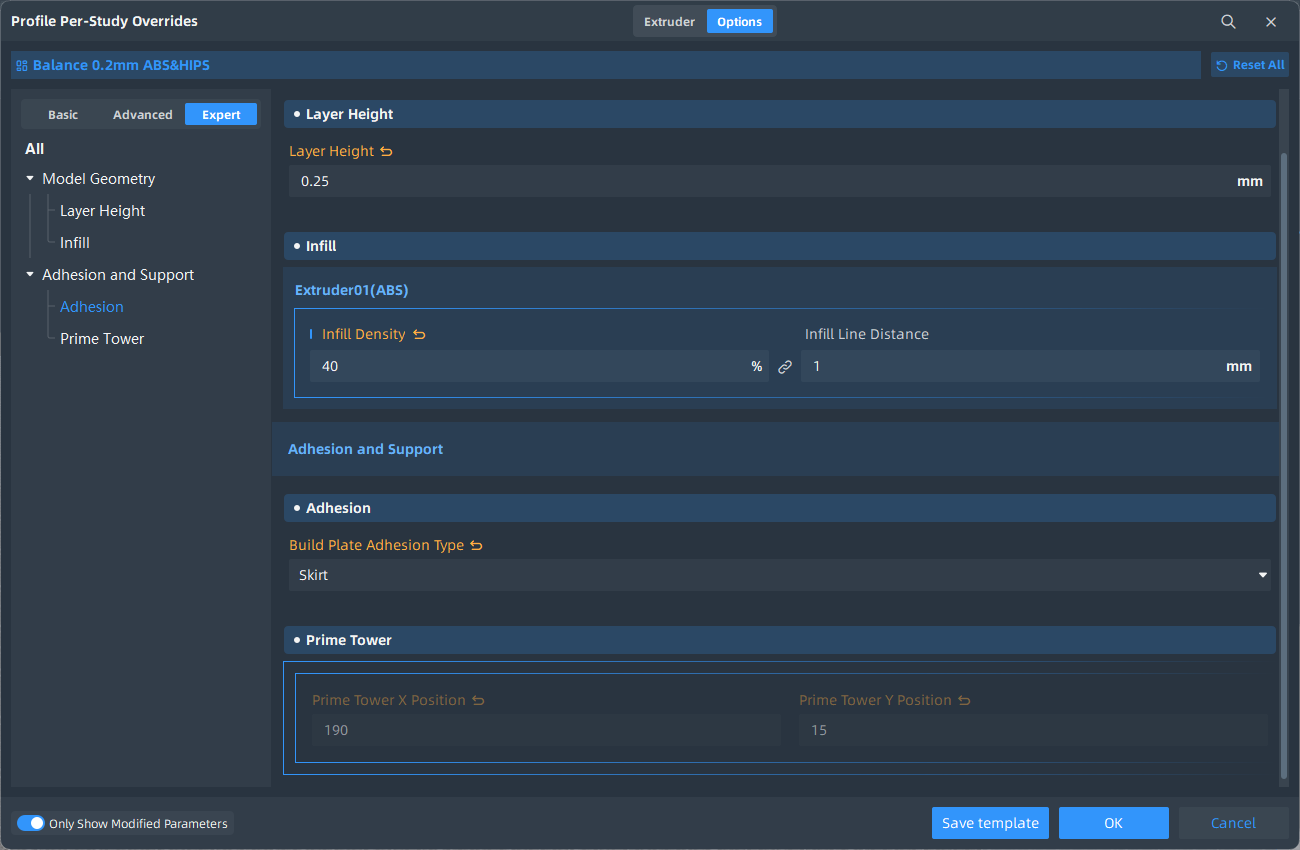

6. Toggle to show modified parameters only in Profile Per-Study Overrides dialog and Profile template editing dialog, so that you can get all parameters changed in one-click.

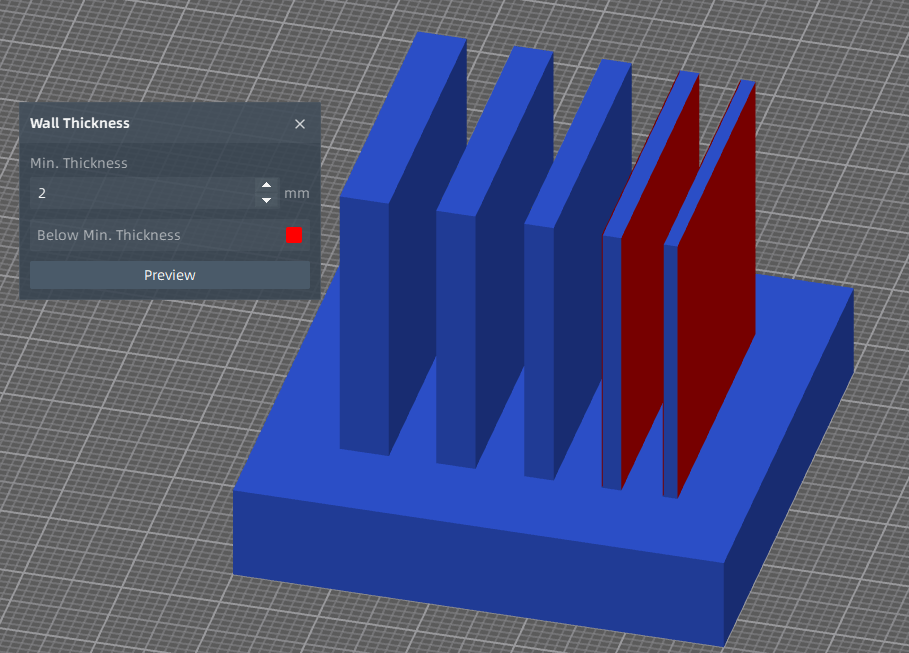

7. DFAM Check: Detect and visualize surfaces and meshes within specified thickness threshold, which helps to check if certain geometries fall below the resolution of the printer.

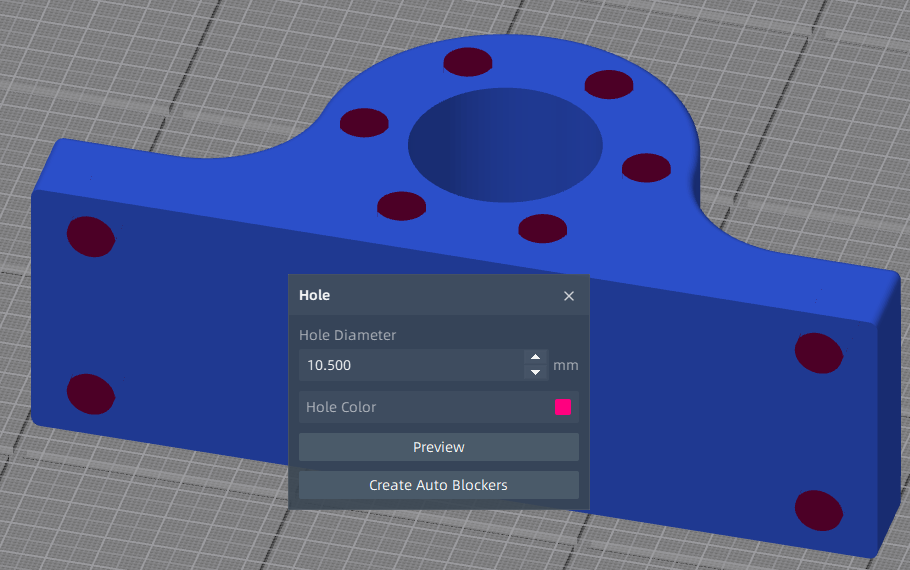

8. DFAM Check: Recognize cylindrical holes within specified diameter and create support blockers adaptive to their support surfaces in batch.

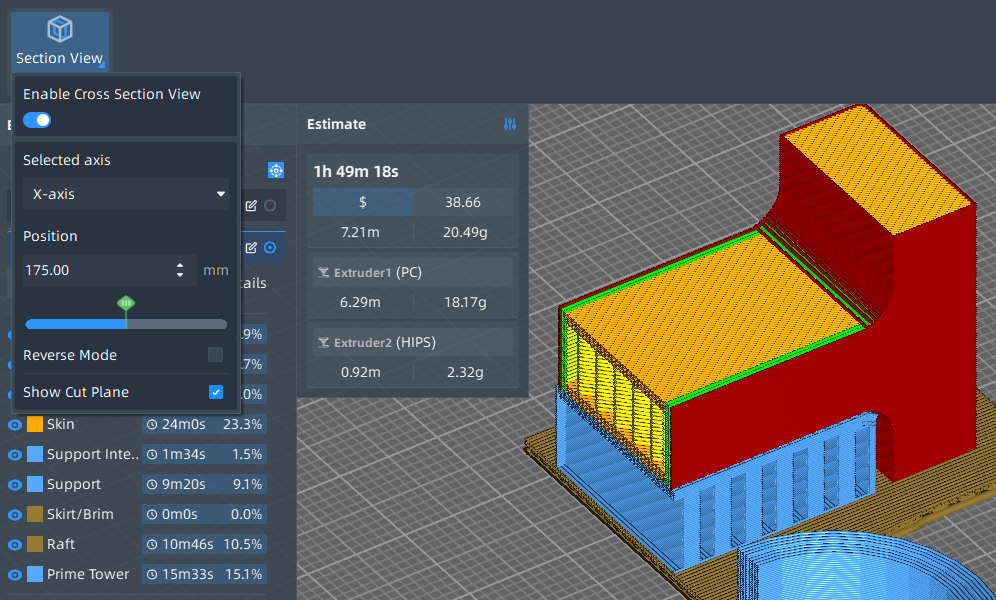

9. Support to create section view in Preview and Compare besides Prepare environment.

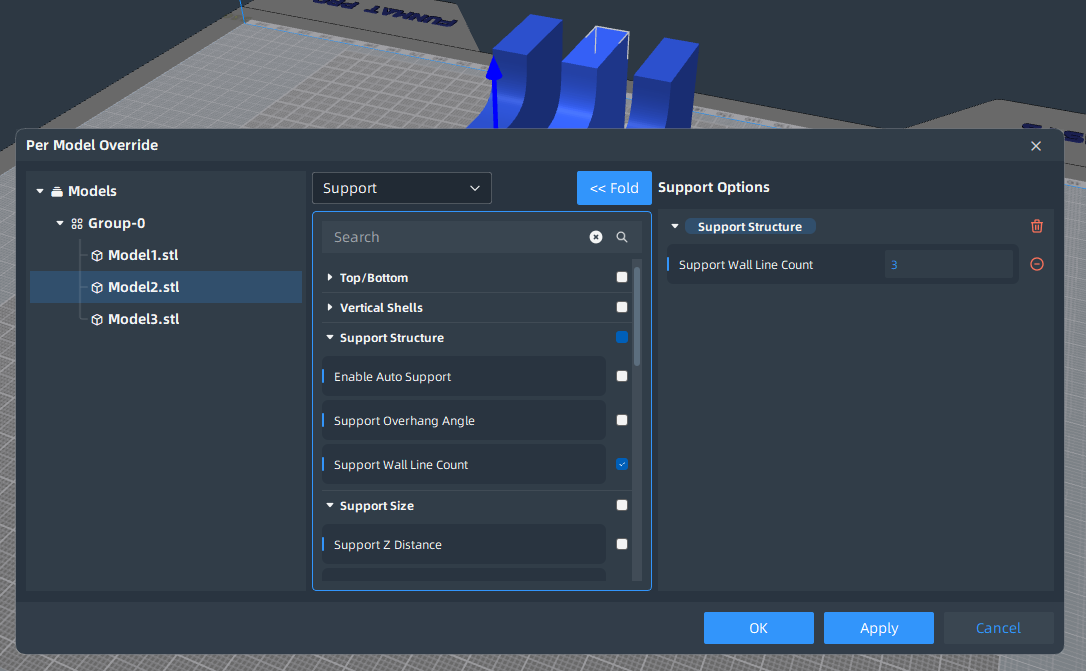

10. Models with different Per-model Override settings (Modifiers) can be grouped together, and each model in the same group can be selected to define different Per-model Override settings as well.

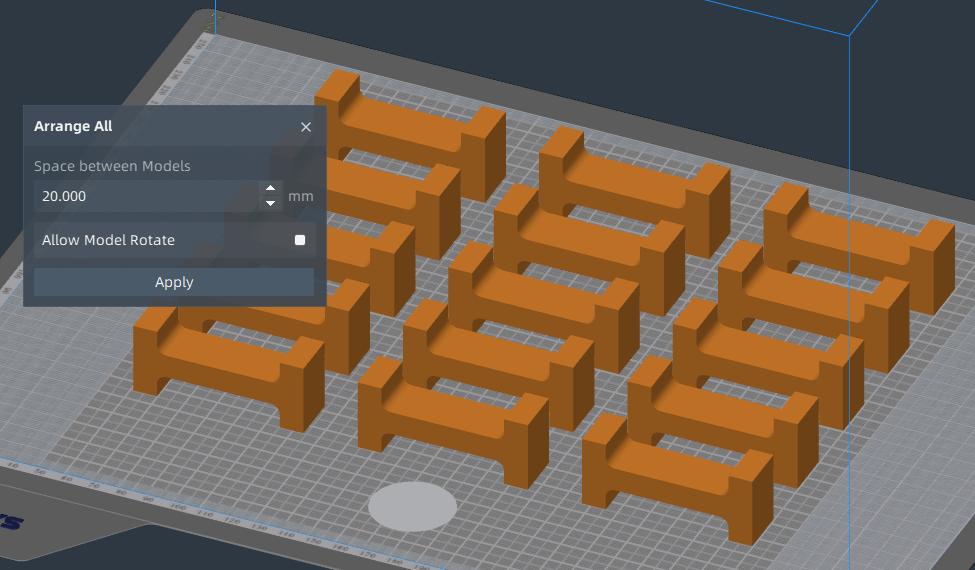

11. Optimize “Arrange All Models” function to fully utilize the space of build plate, and you are allowed to define the distance between models and choose to rotate models or not. And “Insert Model” command benefits from this improvement on location calculation of model placement as well.

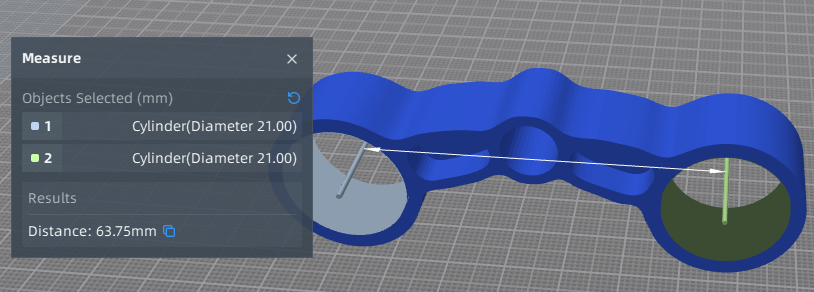

12. Measure tool supports cylindrical surface detection and measurement.

13. Toggle to hide non-model related feature types of printing path automatically and temporarily to Rotate, Pan and Zoom In/Out view in Preivew environment, which may make view manipulation more smoothly for some large volume slciing results.

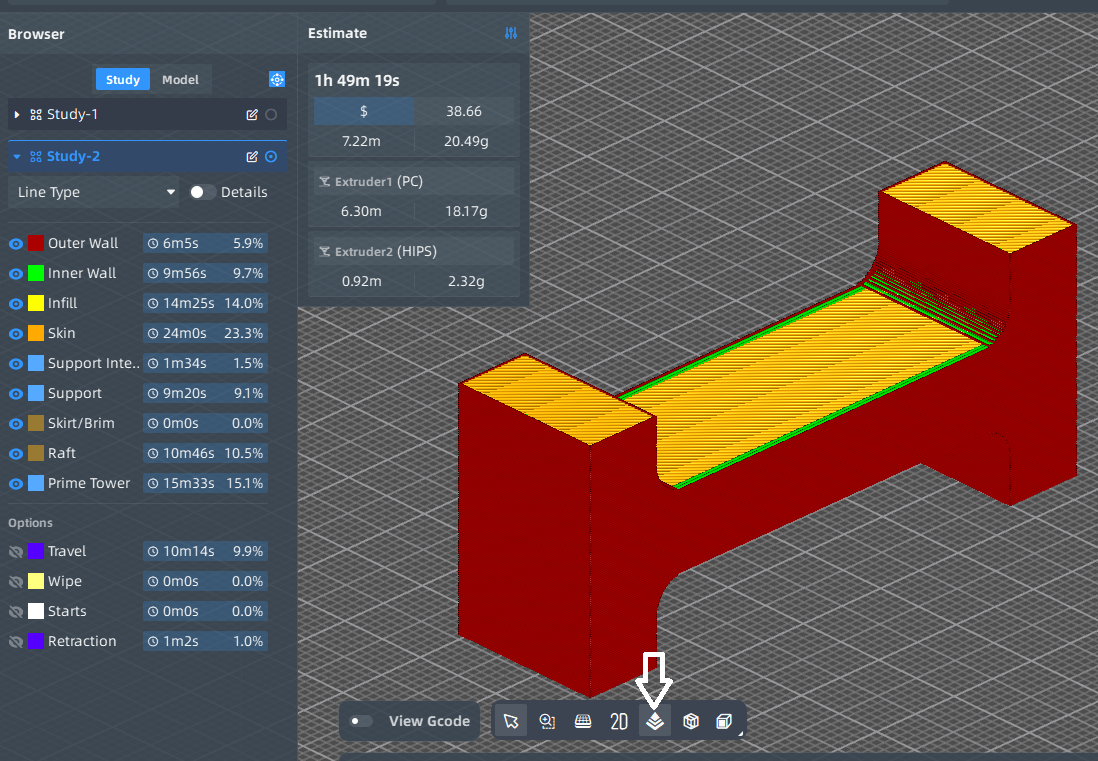

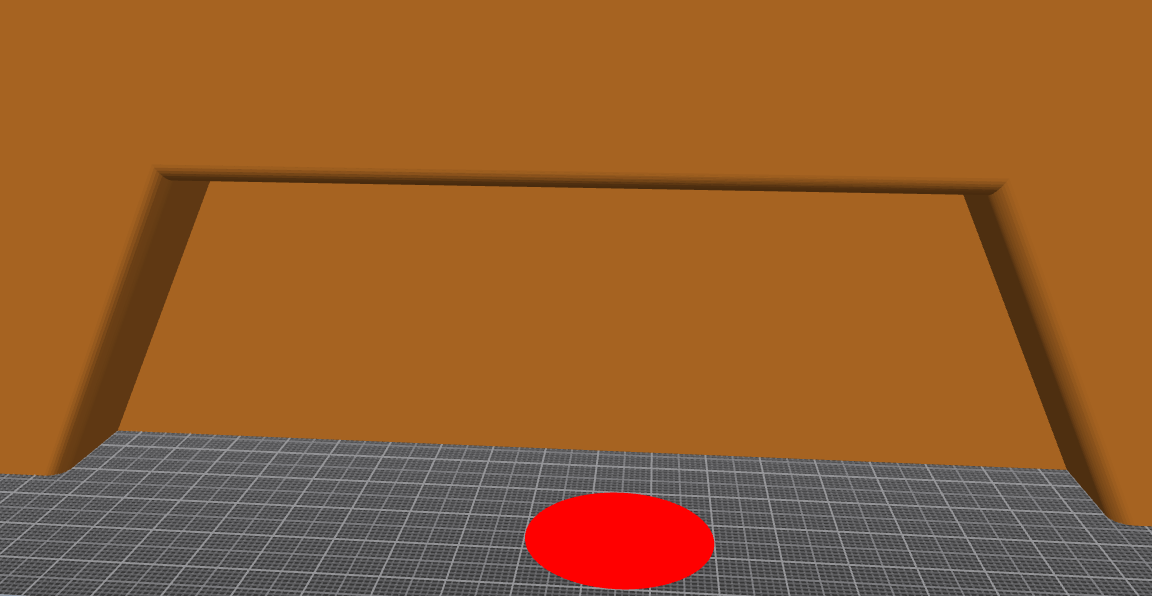

14. Potential collision between print model and prime tower can be detected, and the preview of prime tower in prepare environment will be shaded as red.

15. Expose toolheads in both windows in Preview environment so the current print locations can be seen clearly.

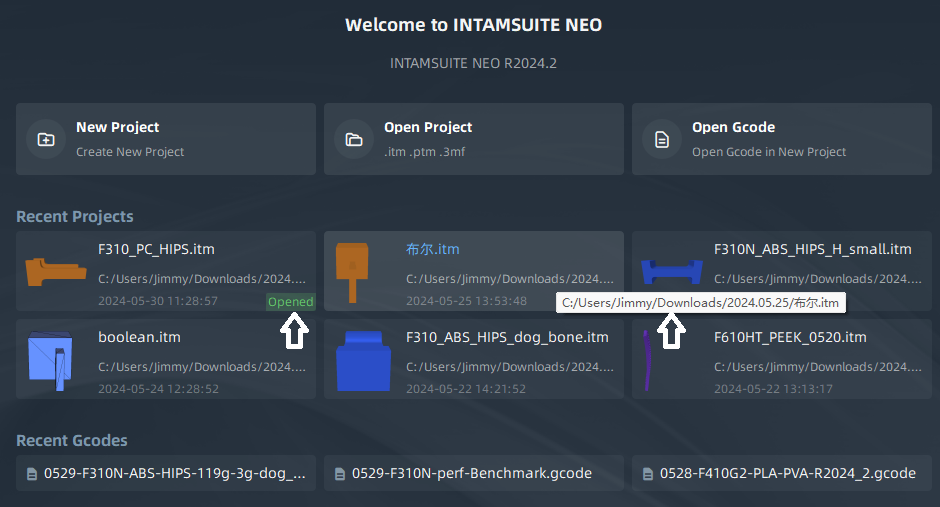

16. On main page, show the open status of each project and the full storage path of the project under mouse hover.

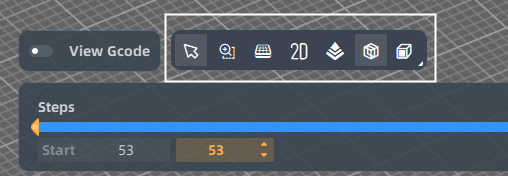

17. Add navigation toolbar in Preview and Compare Enviroment

18. Provide toggle button on ribbon to turn auto support and prime tower on/off directly and no need to enter Profile Per-Study Override dialog.

19. User interface language extends to support French and Traditional Chinese.

20. Swtich to view Wipe location on print path in Preivew environment.

21. Export all custom templates in batch from the library and then get the package file imported for sharing. (PMS-2508)

22. Find and use recent models from application menu.

23. Navigate to the last viewed position in Profile Per-Study Override dialog.

24. Add the command of “Insert Model” on Quick Access Toolbar.

25. Study tab on Browser is always activated when entering Preview environment.

26. Show the progress to open big project file.

27. The Auto Update window always show the new features list of the latest version, even if you have already finished upgrading.

28. When previewing support surfaces, those of them in direct contact with the build platform will be excluded.

29. Supported blockers are included in exported 3mf file and can be re-used once being imported next time.

30. All models in the same file are inserted and placed as a “group” on build plate. In other words, the relative distance between models will be preserved initially when they are imported as the same model file.

31. The printer type of FUNMAT PRO is supported. Please contact support team to get the related printer templates and then get them imported into INTAMSUITE NEO.

32. Optimized combing mode to have nozzle travel as much as possible inside the model.

33. Optimized position and alignment of Z seam.

34. Supported “Retract While Wiping” for wipe retraction mode for outer wall, inner wall, support, infill, skin.

35. Extended accelaration and jerk control to top, bottom, bottom skin, support roof and support floor.

36. Enabled the related support parameters when Auto Support is disabled.

37. Extended to control Travel Acceleration Between Walls, Travel Speed Between Walls and Travel Jerk Between Walls.

38. Optimized overhangs recognition, and also its printing speed and fan speed control.

39. Extended fan speed overrides to bottom skin outer wall, bottom skin inner wall, support roof skin and support bottom skin.

40. Updated the feedback collection page functionally and visually.(PMS-2592)

41. Hover to expand the dropdown list of environment (Prepare, Preivew, Compare, Print), besides clicking.(PMS-2592)

¶ Material & Profile Updates:

- SP3030 is recommended as the suppport material for certain materials in all printer types, and related profile templates are included as well.

- FUNMAT PRO 410: Updated build plate temperature and chamber temperature for PA6-CF and SP3030 material.

- FUNMAT PRO 410: Added 4 new materials, including -

- PET-CF with HIPS as recommended support material.

- PET-GF with HIPS as recommended support material.

- PPA-CF with SP5010 as recommended support material.

- PPA-GF with SP5010 as recommended support material.

- FUNMAT PRO 610HT: Provided profile templates for PC-FR and Hips material.

- FUNMAT PRO 610HT: Updated bottom skin parameters for PEI 9085.

- FUNMAT PRO 610HT: Updated raft print process parameters for PPSU.

- FUNMAT PRO 610HT: Updated support print process parameters for SP5080.

- FUNMAT PRO 610HT: Added 2 new materials, including -

- PET-CF with HIPS as recommended support material.

- PET-GF with HIPS as recommended support material.

- FUNMAT PRO 310: Updated print process parameters for PLA, PA6-CF, PA12-CF etc.

¶ Fixed Issues

- Due to microsft dependency, Missing dll(s) to launch the program, including VCRuntime140_1.dll, MSVCP140.dll, msvcr100.dll, msvcp100.dll etc. (PMS-2560)

- In case you continue to encounter similar problem, please refer to Missing_DLLS for details.

- Minor supports are created around support surfaces with adaptive support blocker.(PMS-2665)

- Raft Extra Margin and Raft Smoothing don't work when Build plate adhesion extruder and raft base extruder assignment are different in Profile Per-Study Overrides. (PMS-2714)(PMS2837)

- Support interface is not generated in some cases. (PMS-2194)

- Large indicator surface appears to align selected face with build plate via On Face command. (PMS-1164)

- Fail to group different modifiers (models with Per-model Override settings) for moving together. (PMS-2465)

- Wall line cout is not updated along with wall thickness in both profile per-study override and profile management dialog. (PMS-3015)

¶ Known Issues or Limitations

- Open INTAMSUITE V4.3 3mf file, we only support open the part models.

- The program's performance on AMD Radeon graphics cards is relatively poor compared to Nvida graphics cards.

- Cannot play the webcam LiveView remotely for FUNMAT PRO 410 and FUNMAT PRO 610HT.