¶ Layer shift

Sometimes layer shift issue happens, we'll talk about some roots and solutions of it here.

In general, "layer shifting" is related to deviations from the actual coordinate system of the nozzle. Both software and hardware can cause abnormal changes in the actual coordinates of the nozzle.

¶ 1. Software - gcode file

The G-code file contains motion commands for the X, Y, and Z axes. If there are issues during file generation, transmission, etc. (such as garbled file memory, sudden changes in movement distance, viruses, etc.), it may result in the "layer shifting" issue during printing. You can use "Note" to view the corresponding G-code file

¶ 2. Hardware

Observe the "layer shifting" phenomenon to determine whether it occurs along the X-axis or the Y-axis, and then inspect the corresponding hardware

(1) Lubrication

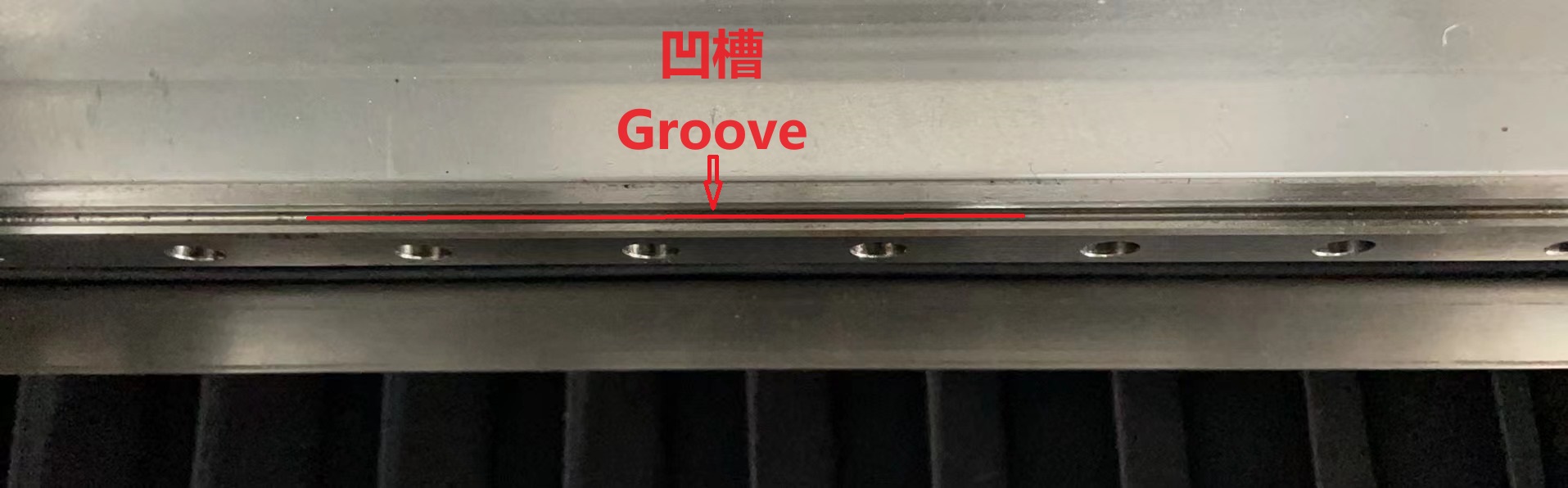

If the "layer shifting" issue occurs along a certain direction, check the lubrication condition of the hardware in that direction. Please clean and lubricate the corresponding rails and bearings (high-temperature resistant lubricating grease - it is recommended to use Krytox-GPL225 grease). When lubricating, if it is a square linear bearing, pay attention to lubricating the recesses on both sides (Figure-4)

(2) Tension of driving belt

When the tension of the driving belt is inappropriate (usually too loose), the belt may skip teeth on the main/idler pulley, causing deviations in the actual coordinates of the nozzle, which can lead to the "layer shifting" issue.

Therefore, when “layer shift” occurs, it is necessary to check the tension of the driving belt corresponding to the axis. The default tension of the driving belt was generally set between 35-40 Newton-meters. If there is no instrument to measure the belt tension on site, you can use an app on Apple phone called "Fine Tuner" (Figure - 5) to test the Hertz value generated by manually flicking the belt (Figure - 6, this test needs to be conducted in a very quiet environment, otherwise it will be interfered by other sound sources). The following provides a range of Hertz values for reference:

| Model | Axis | Range |

| FUNMAT PRO 410 | X & Y | 50 - 55 HZ |

| FUNMAT PRO 310 | X | 70 - 78 HZ |

| Y | 50 - 55 HZ |

|

|

If the frequency value is outside the recommended range, please try to adjust the tension of the belt.

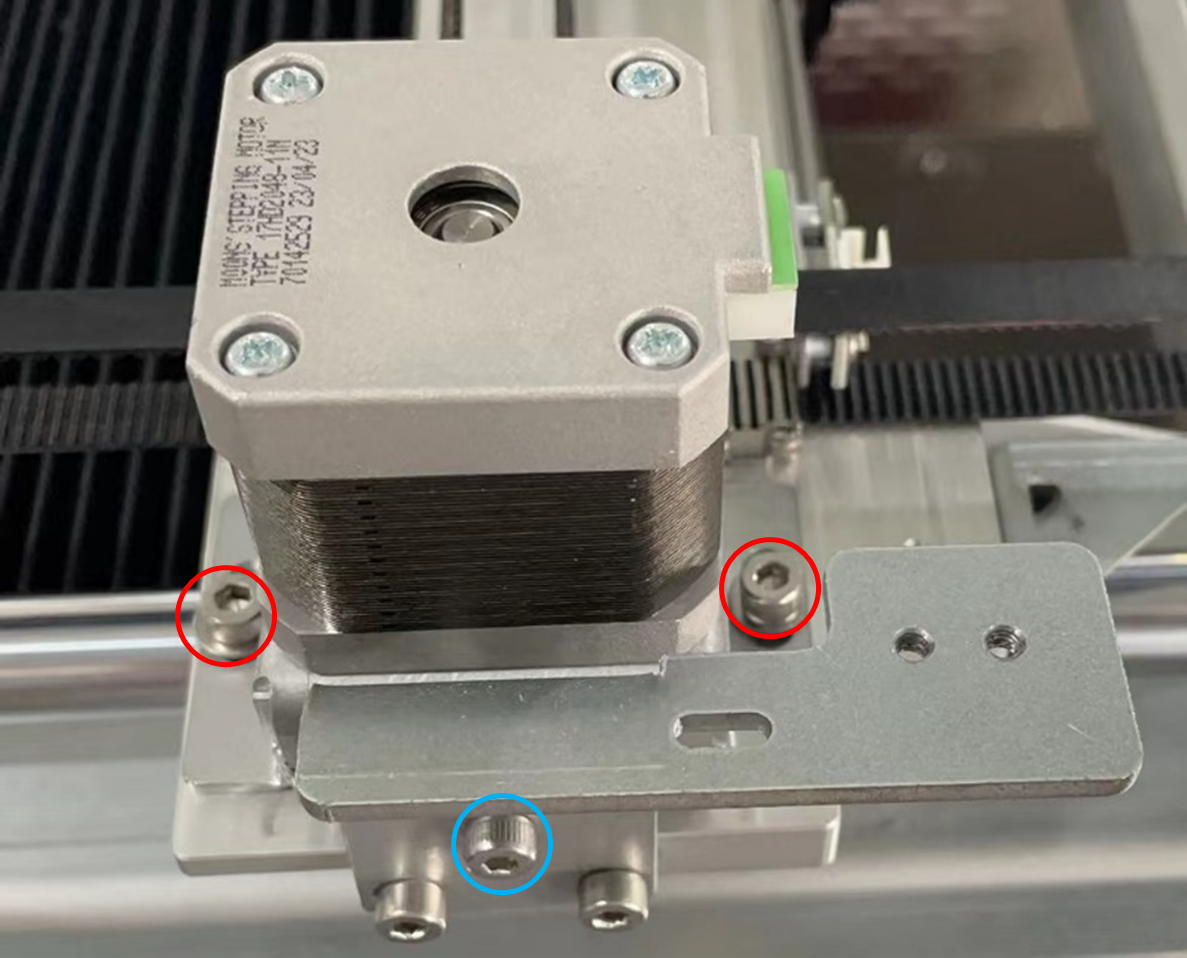

- For adjusting the tension of X driving belt (FUNMAT PRO 310 NEO as the example), firstly locating driving motor of L/R nozzle(Figure - 7), push them back to their home position, slightly loosen the 2 locking screws red highlighted in figure - 7, then loosen/tighten the adjusting screw blue highlighted (loosen - decrease tension, tighten - increase tension). When adjustment was completed for one time, tighten the 2 locking screws red highlighted, move 2 extruder assemblies back and force in X axis by hand, and push them back to home position, and do the measurement again. Repeat above steps till the value is within the range.

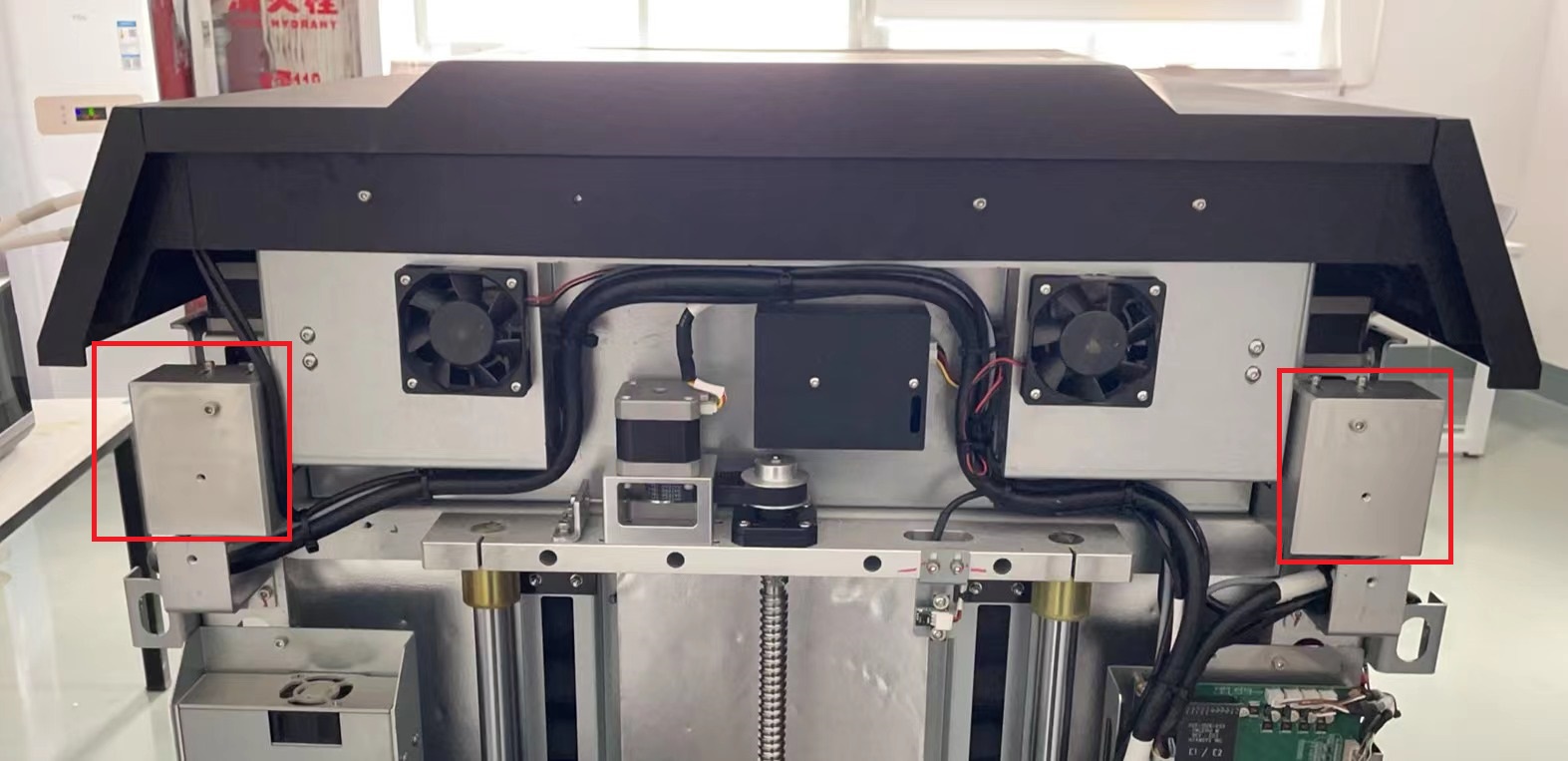

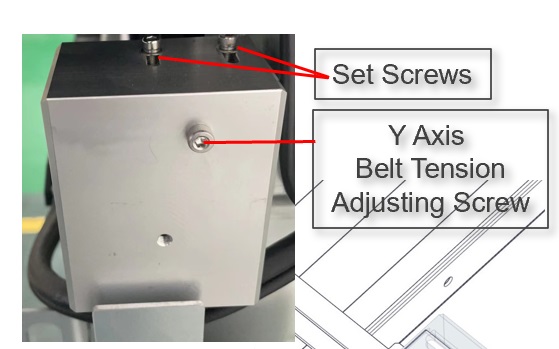

- For adjusting the tension of X driving belt (FUNMAT PRO 310 NEO as the example). Remove back cover, locate the 2 mental blocks that are for adjusting Y driving belt (Figure - 8). Slightly loosen the 2 locking screws, then loosen/tighten the adjusting screw (loosen - decrease tension, tighten - increase tension). When adjustment was completed for one time, tighten the 2 locking screws, move extruder assembly back and force in y axis by hand, and push them back to home position, and do the measurement again. Repeat above steps till the value is within the range.

|

|

(3) Other Hardware

After lubrication and maintenance, and confirmed the tension of the X/Y axis drive belts is within the range, please inspect the hardware in the direction where the "layer shifting" occurs.

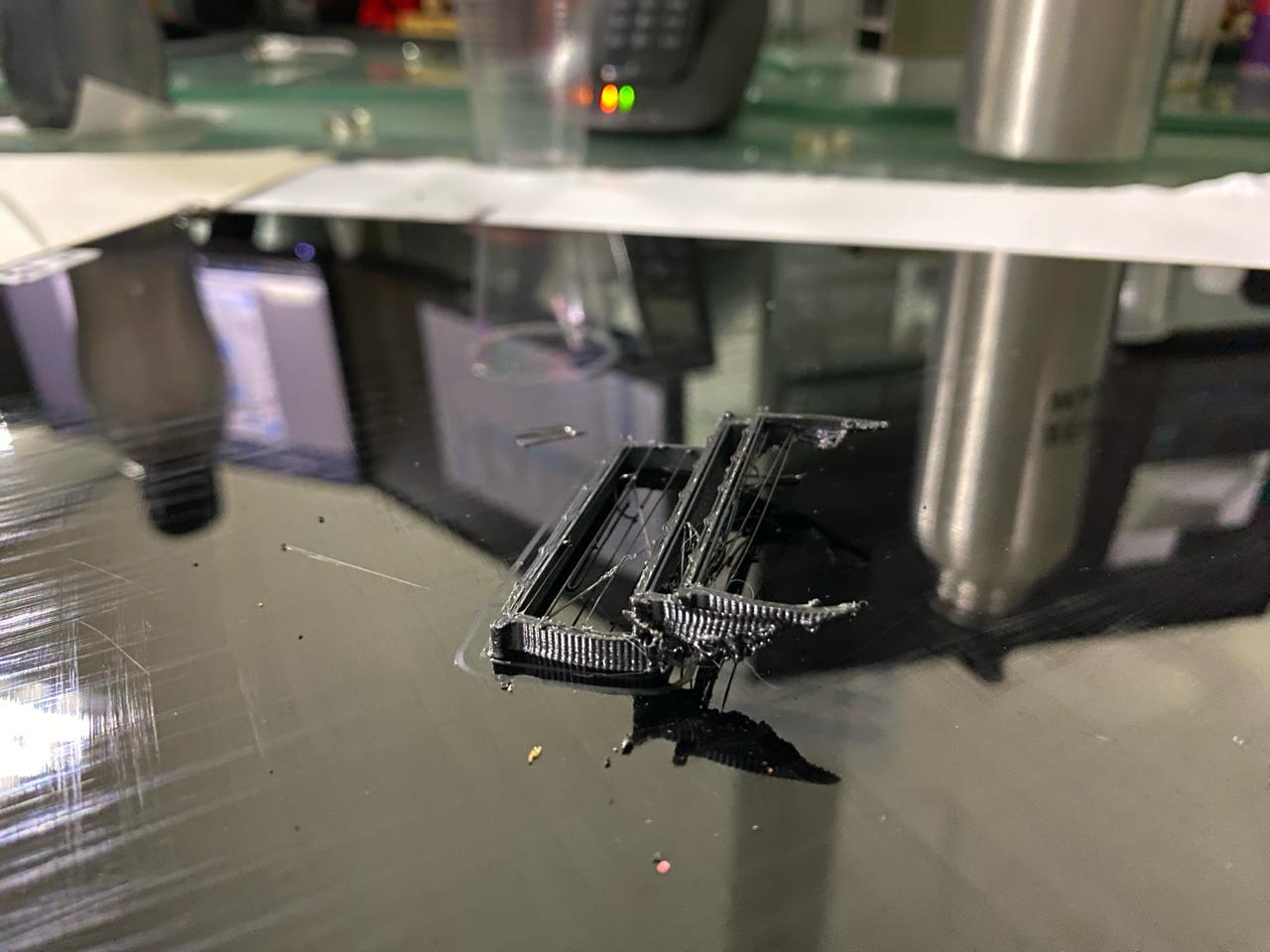

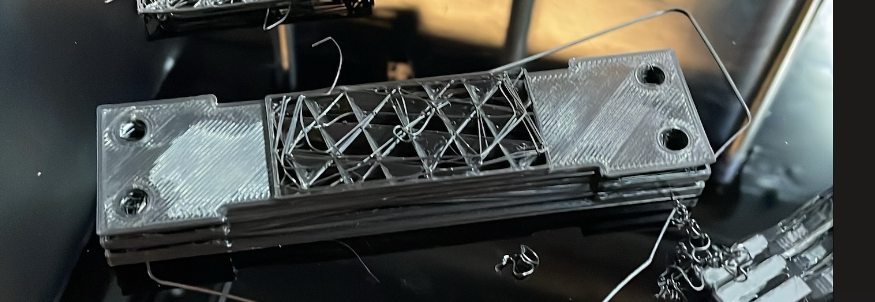

- Check if there's issue with the linear bearing(for example Figure 10 & 11)

|

|

- Manually move the print head assembly in the X/Y direction to feel whether the movement is smooth and to check for any areas where there is resistance. If there is a noticeable change in resistance in a particular area, please contact with INTAMSYS service team.

- Manually move the extruder assembly along the X/Y axss, pay attention to whether there are any unusual sounds during the movement.

- Check if there's issue with driving and idle pulley assembly of driving belt and the belt clamp.

Please contact with INTAMSYS service and support team if anything abnormal was found in above aspects.