¶ E333 - Y limit switch is triggered

¶ Y limit switch is triggered

¶ Steps:

(1) Check if the size of model is over limitation at Y Axis, or the model is very close to the front side. Turn, rotate, adjustor relocate the model to meet the size limitation of machine.

(2) If the size of model in Y axis is much smaller than limit size, and the distance between 2 edges of model and 2 edges of build-plate in Y axis is reasonable, then we should consider if it is Y limit sensor issue.

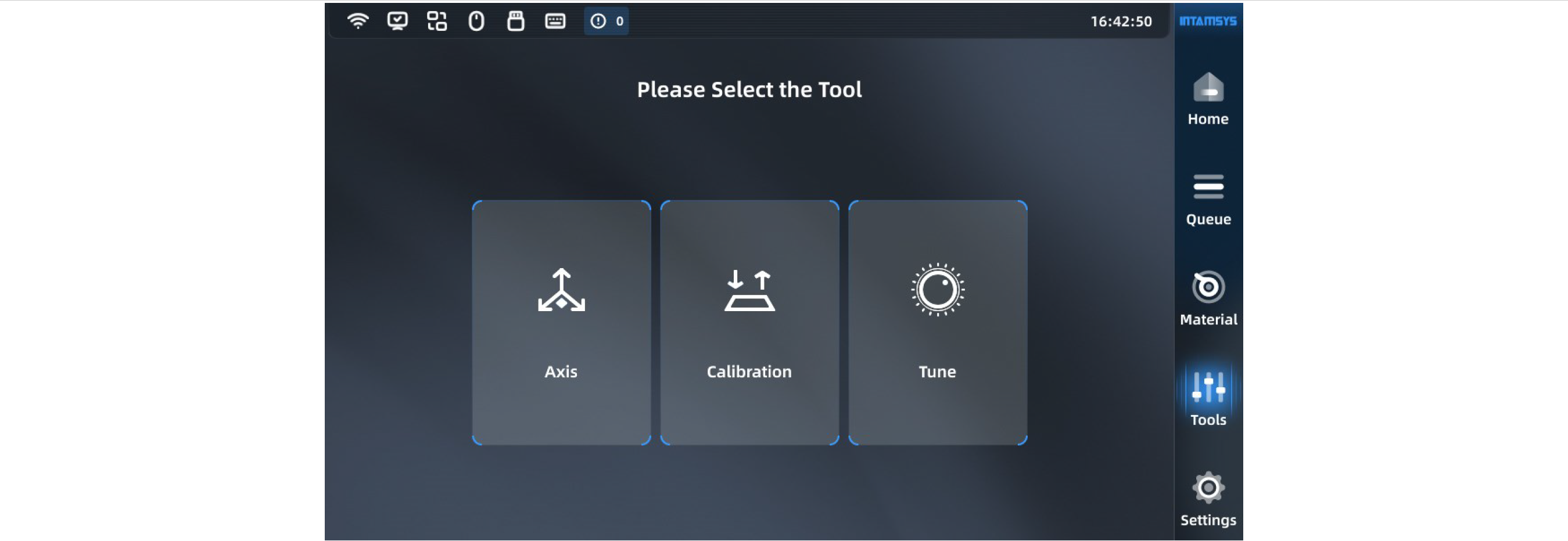

- Click “Tools” - “Axis” - “Y axis” - “home” (Figure - 1, 2). If homing works normally, the sensor could be mis-triggered during molding, check if there are dirt or debris or else around the Y limit sensor (position of Y limit sensor). Meanwhile, re-plug plug J32 in main board (in middle left of main board).

(3) If homing is abnormal, and there are no dirt or debris around limit sensors, we need to test if sensor works normally. Click “System” - “Machine” - “More settings” - disable the motor (Figure - 3) in touch screen, thus X & Y axis can be moved manually

(4) Move the bridge of extruder assemblies (Y axis) to the most front, Y limit sensor should be triggered at this moment, and the green light of sensor should be on (Figure - 4).

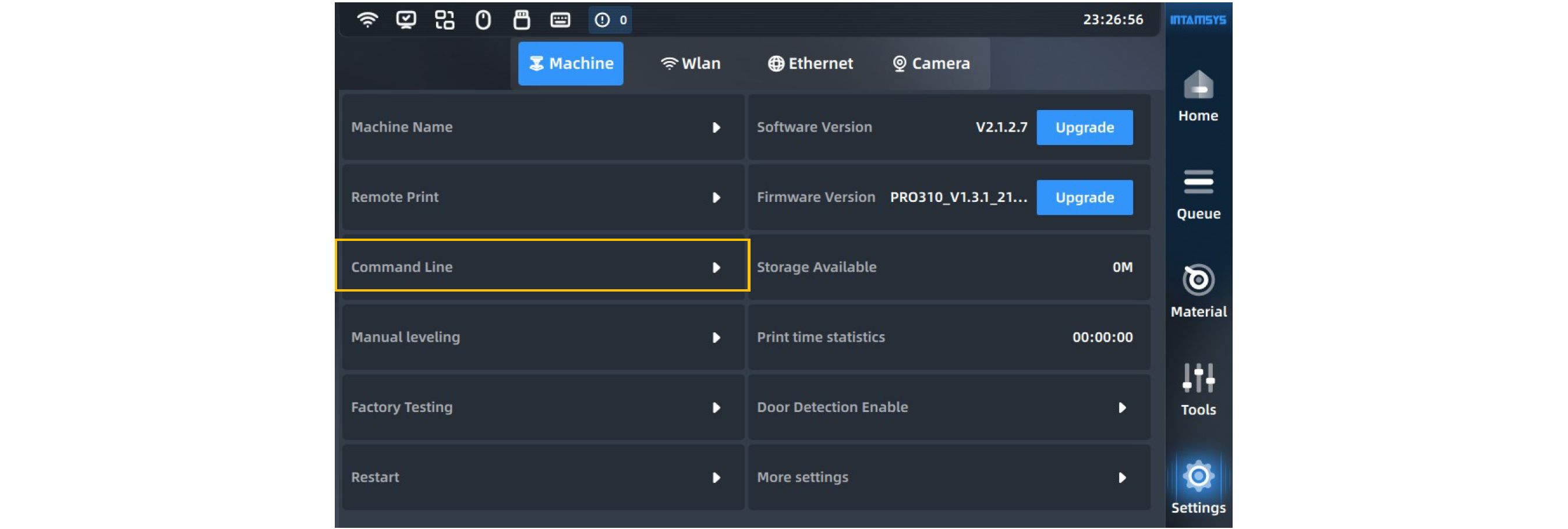

(5) Then, click “system” - “machine” - “Command Line” (Figure - 5)

|

|

- move the bridge of extruder assembls (Y axis) away from Y axis front limit sensor, the light of sensor should be off, then input the order “M119” in bottom blank and click “send” ( Figure - 6 ). At this moment, the sensor feedback value "Y_MIN: 1" should be displayed at the position of "1" on the screen. After that, move Y axis to the most front to trigger the front limit sensor, then input order “M119” again, at this moment, the sensor feedback value "Y_MIN: 0" should be displayed at the position of "2" on the screen. If the values are abnormal, please replace the left limit sensor. (Step of replacement).

(6) If issue persist after replacing Y front limit sensor,

- Please re-load the firmware.

- If re-loading firmware didn't work, please replace the main board. (Step of replacement)