¶ Rails – Y Axis

¶ Steps:

a. Turn machine off, use knob wrench (Figure 1.4-1) to remove left, right and back covers.

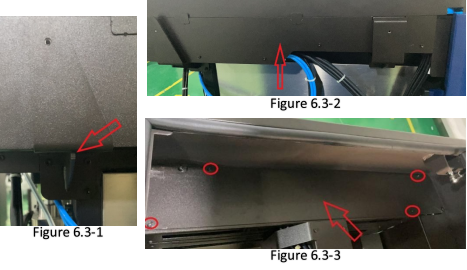

b. Move to left side of machine, use 3mm Allen-Key to loosen 3 screws and remove the triangle arm. Figure 6.3-1

c. Use 2.5mm Allen-Key to loosen 5 screws and remove the cover on the left side. Figure 6.3-2

d. Open the top door, use 2.5mm Allen-Key to loosen 4 screws and remove the left inner cover. Figure 6.3-3

e. Use 2.5mm Allen-Key to loosen 4 screws on the left inner cover (Figure 6.3-4). You cannot remove the cover, and remove the screws and hang it there. This makes you now available to left Y rail.

f. Use 2.5mm hex screw driver to loosen the 2 screws on the top of the right inner cover, use 2.0mm hex screw driver to loosen the 2 screws on the left side of this right inner cover. Figure 6.3-5

g. Use 3mm screw driver to loosen 4 screws to remove the right front arm. 2 screws outside, 2 screws inside. Figure 6.3-6. Now Y axis right rail is available

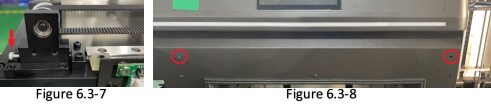

h. Use 2.5mm screw driver to loosen the push-pull screw (Figure 6.3-7) through the hole (Figure 6.3-8), this releases tension of left and right Y axis belt.

Suggestion: it’s better to feel the tension by your finger before loosening the tension. Since there’s no meter on site, you are not able to set the tension precisely as default. Poor blet tension makes negative effects on printing.

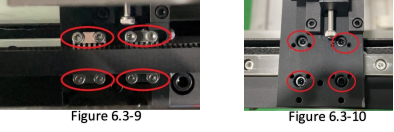

i. Use 2mm screw driver (a long T will be better here) to loosen 8 screws and remove the belt and 2 clamps of belt on both left and right side. Figure 6.3-9. Now the bearing block is available to you. Figure 6.3-10

j. Use 2.5mm screw driver to remove all the screws on the top surface of Y axis right rail. Lift up the X axis arm on the right a little and take out right Y axis rail.

k. Position the new rail back, and make sure both front and rear side of new rail touches the 2 plastic blocks. Figure 6.3-11

l. Use 2.5mm screw driver to tighten all the screws of Y axis right rails. Use 2.5mm screw driver to tighten the 4 screws to reconnect right side of X axis with Y axis right rail. Figure 6.3-10 (same way to fix the left rail)

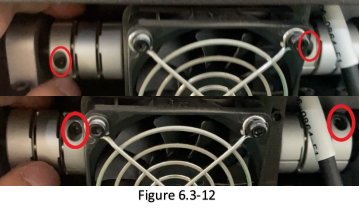

m. To the back side of the printer, loosen 2 screws in each Y axis driving coupler (Figure 6.3-12) to relieve the resistance from motor. This is about to test the parallel between the 2 rails. Then move the extruder assy through Y axis for several times manually, subjectively feel if the movement is smooth. Adjust the position of Y right rail as needed to make the movement smooth.

n. The similar way to replace the left rail. Then, put the belt back, tighten the 8 screws to clamp the belt on both left and right side (Figure 6.3-9)

o. Tighten the push-pull screw (Figure 6.3-7 & Figure 6.3-8) to recover the tension of 2 belts. As step m mentioned, to feel the tension by your finger and adjust it as close as previous.

p. Tighten the screws in 2 Y axis driving couplers to engage Y motion.

q. Put all the covers back following “step a – g”