¶ Build-plate Adhesion Issue

Here we take FUNMAT PRO 310 as the example (the build-plate of other printers are not the same to that of FUNMAT PRO 310, but the way is the same). FUNMAT PRO 310 uses PI panel heating with flexible magnetic build-plate sheet. The adhesion is improved quite a lot compare with the previous platforms using borosilicate glass. Meanwhile, the model is easy to be removed as well.

But, if the leveling is poor , for example, nozzle is far away from the build-plate (out of the range), extruded filament cannot adhere to the build-plate sheet, then warping issue happens through the time goes by during printing. So, how can we know if the leveling is good? we can actually identify it through the look of raft.

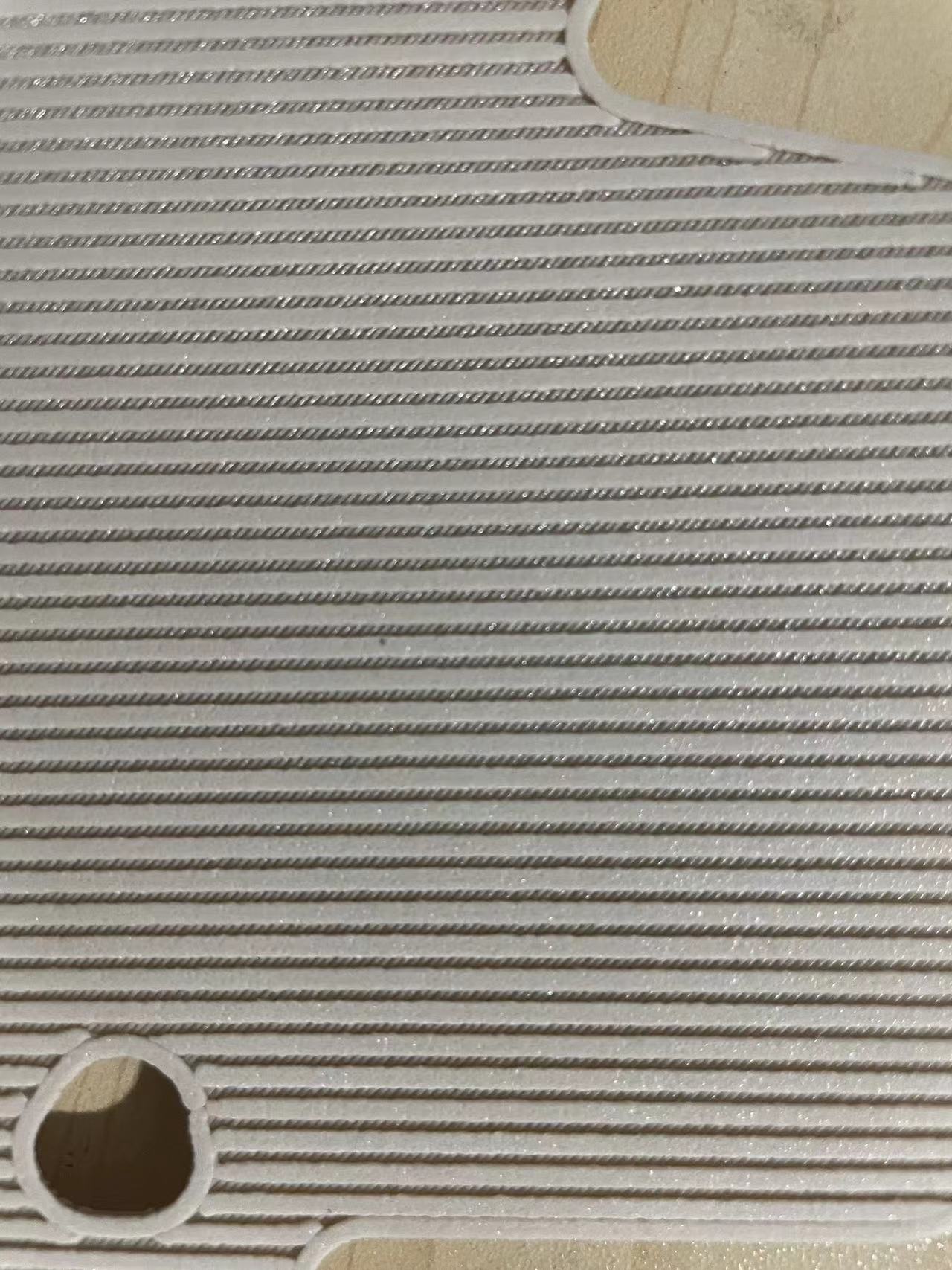

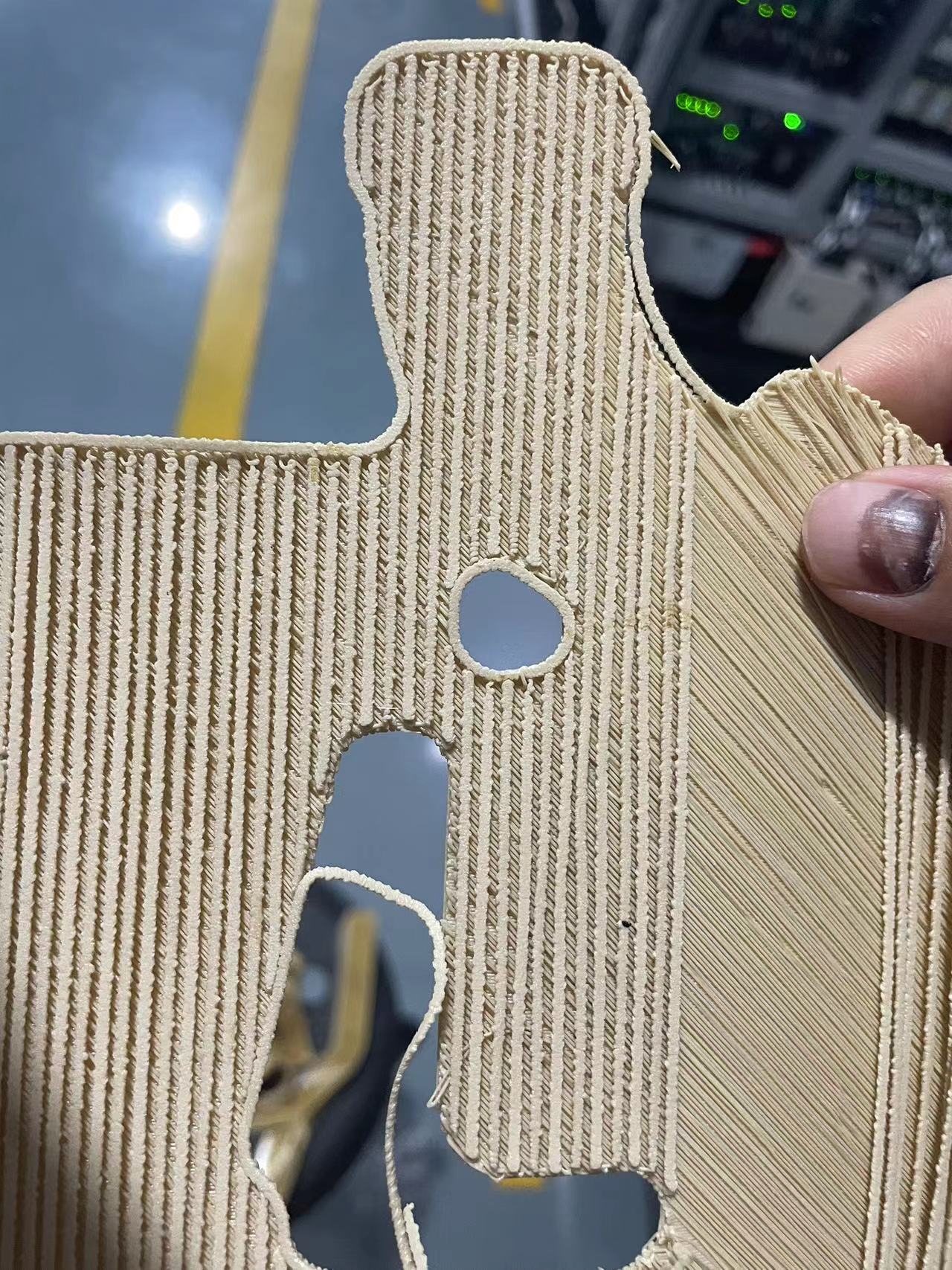

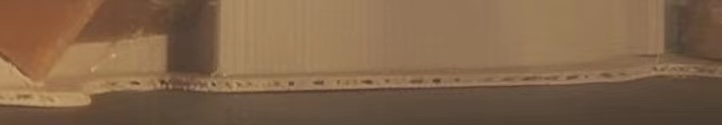

Refer to the figures below:

- Compare figure 1 with figure 2. In figure - 1, the width of extruded lines in the bottom panel of raft are 1.5 times bigger than the gap between 2 extruded lines, which is showing a good leveling. In figure - 2, the width of extruded lines are smaller than the gap, while the extruded lines have a lot of sawteeth on their edges, this is showing a poor leveling.

- Compare figure 3 with figure 4. In figure -3 with good leveling condition, the 4 layers of raft is denser and soilder. In figure - 4, there are obvious gaps among the 4 layers of raft, this is showing poor bonding among the 4 layers.

- The final result is, the model (figure 1 & 3) was successfully done, the model (figure 2 & 4) failed during printing due to warping issue.

|

|

|

|