¶ Support and Overhand

¶ 1. the Propose of “Support”

If there's no “support” placed under the places of model where is suspended, these places will trend to collapse.

¶ 2. Common Support Material

The common support materials can be divided into three major categories: self-supporting (single nozzle printer), strippable support materials, and dissolvable support materials (usually found in multi-nozzle printing devices).

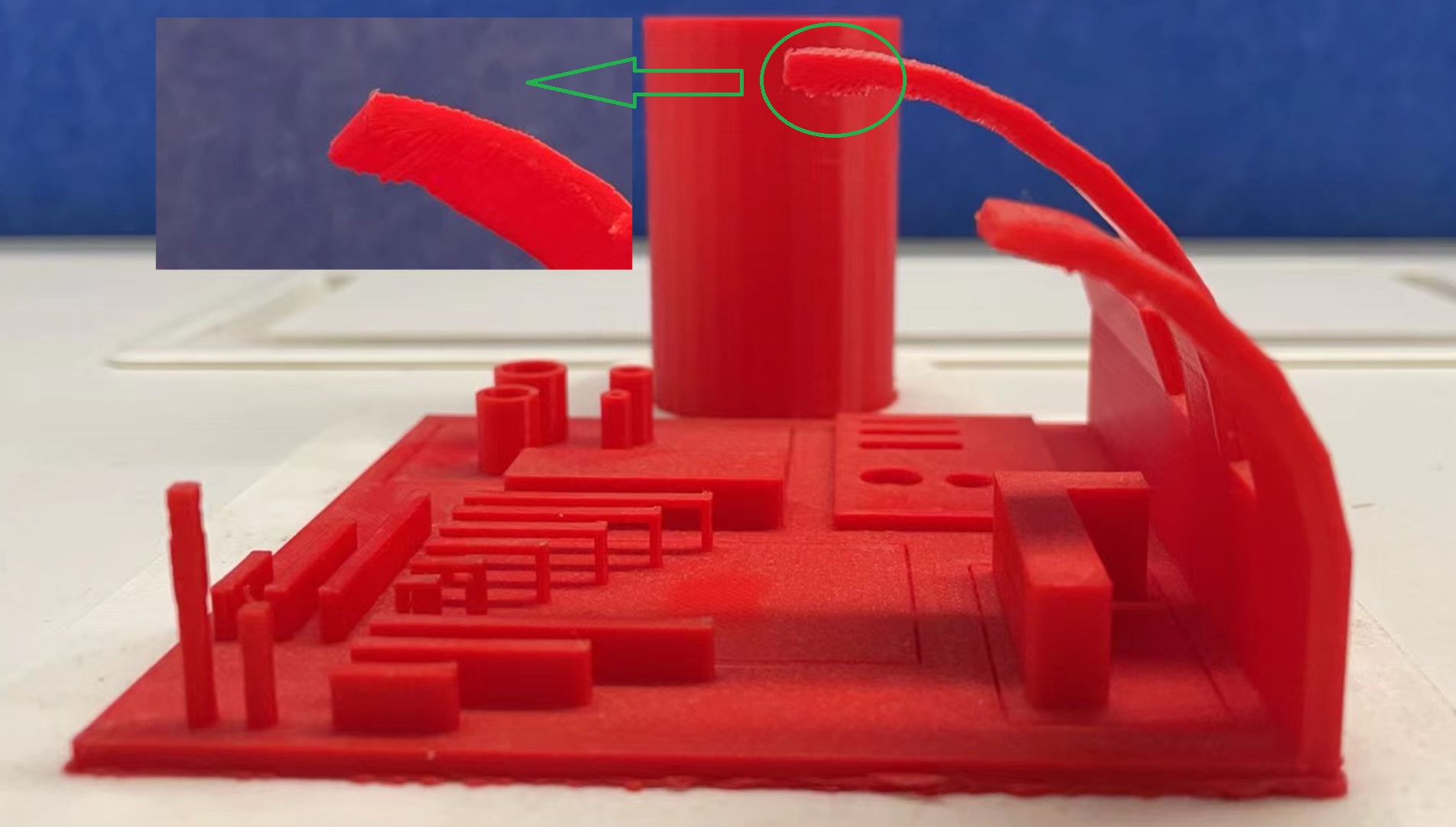

1) Self-supporting. Support material is the same to model. When using “self-supporting”, it is necessary to set an appropriate “Support Z Distance” to avoid excessive bonding between the model and the “support”, resulting in not able to remove support material smoothly during post-processing.

2) Strippable support materials. The support material is different from model's material, it is slightly attached to model and can be manually stripped off by tools. Since the model and supports were printed by 2 different materials, they will not be completely bonded to each other, so the “support Z distance” between them is set to "0" for a better surface quality, and it is also very easy to remove the supports during post-processing.

The common strippable filament (INTAMSYS filament):

| HIPS | fit to ABS, PC, PC-ABS, PC-PBT, PC-FR, ASA - strippable materials |

| SP5000 | fit to PAEK - strippable. It is also dissolvable in ethyl acetate solution |

| SP5040 | fit to PEI 9085 - strippable |

| SP5080 | fit to PEI 1010 & PPSU - strippable |

3) Dissolvable support materials. There are two categories, water-soluble support materials and chemical solvent-soluble support materials.

The common water-soluble filament (INTAMSYS filament):

| SP3030 | Fit to ABS+ | The temperature resistance of water-soluble supports is generally lower than that of strippbale supports. Therefore, when the main printing material requires a certain high chamber temperature, water-soluble supports are more likely to soften, leading to a reduction in the strength of the support part. This is especially true when printing larger and taller models, where the support part may bend, collapse, or even fall over. Therefore, it is necessary to choose reasonable support materials and support structure settings based on actual application conditions, and even use interface-support solution to avoid such phenomena. |

| SP3040 | Fiit to ASA, PA, PA6-CF, PLA, TPU 95A, water-soluble as well as strippable | |

| PVA | Fit to PA, PA6-CF, PLA, TPU 95A, water-soluble |

The common chemical solvent dissolvable support materials

| SP5000 | Fit to PAEK, strippable as well as soften/dissolved in ethyl acetate solution |

¶ 3. Settings of “Support”

|

Enable or disable “Auto support” |

|

|

|

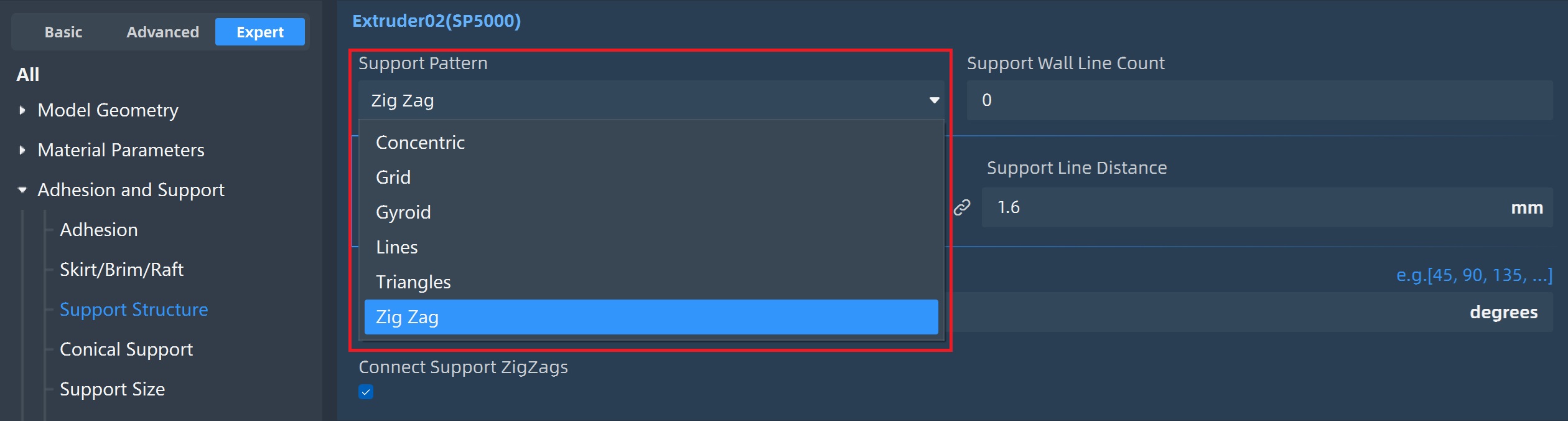

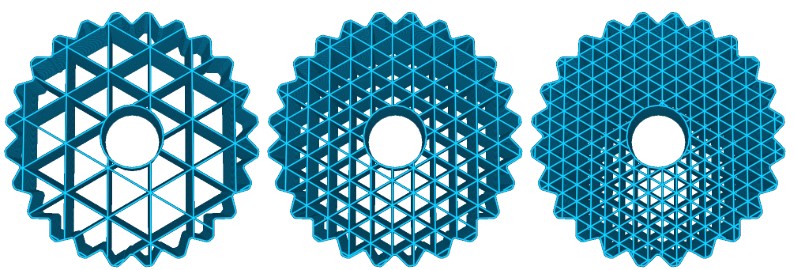

Support Pattern

|

Different structures provide varying levels of structural strength, and their ease of stripping also varies accordingly.  |

|

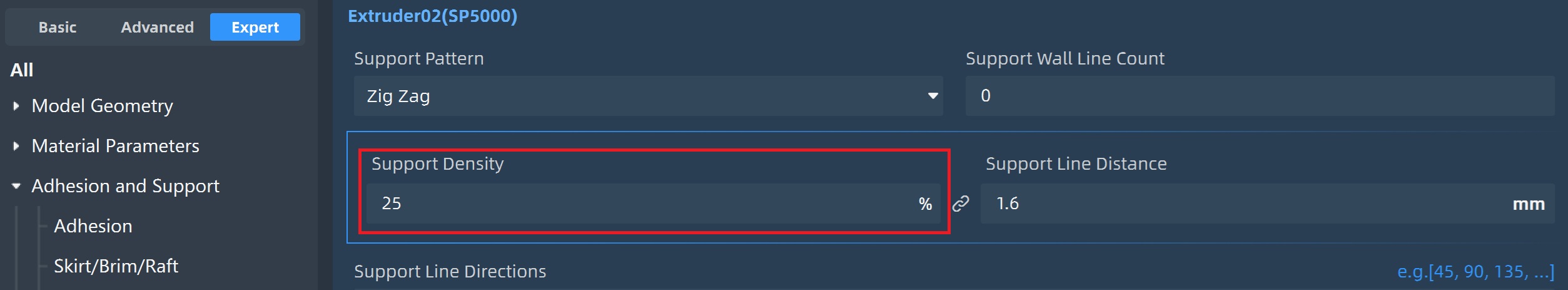

| Support Density |

The higher the density of the support structure is set, the stronger strength it will be, but they will be more difficult to remove and will take more time to print.   |

|

|

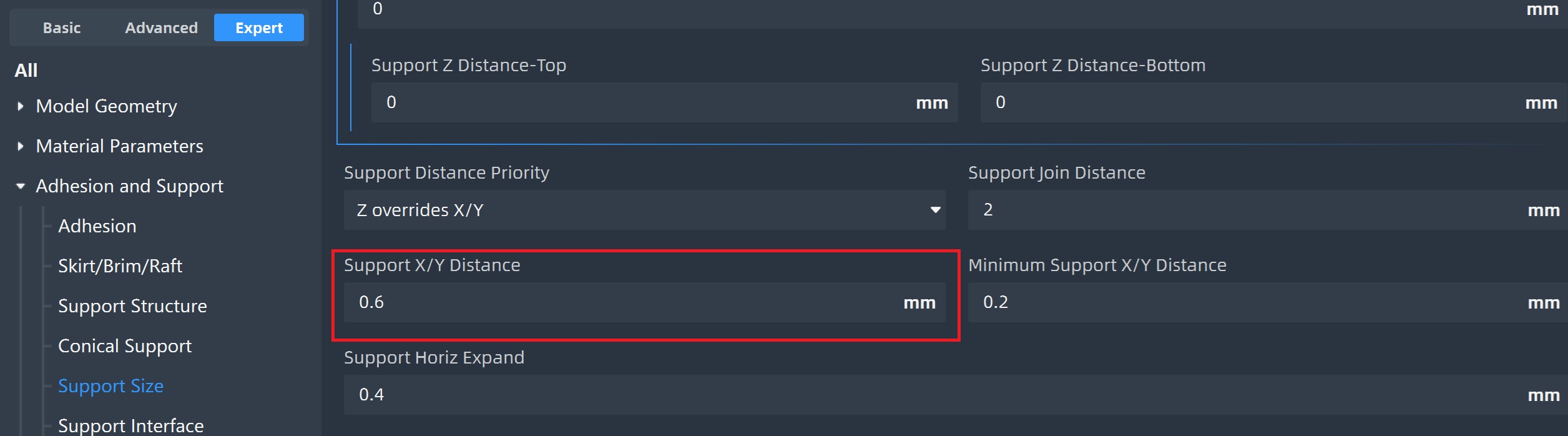

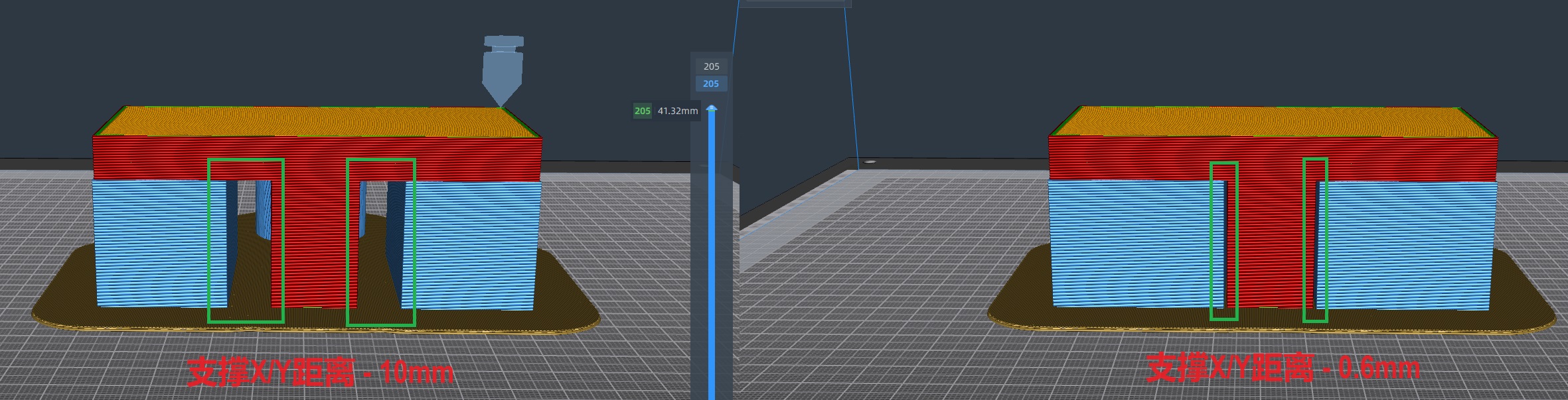

Support X/Y distance

|

In the plane of X&Y axis, “Support X/Y distance” effects printing time and ease of removing supports. At the same time, the bridging capability of model's material must be considered when changing this setting. An overly large setting may lead to collapse in areas without support at the bottom,   |

|

|

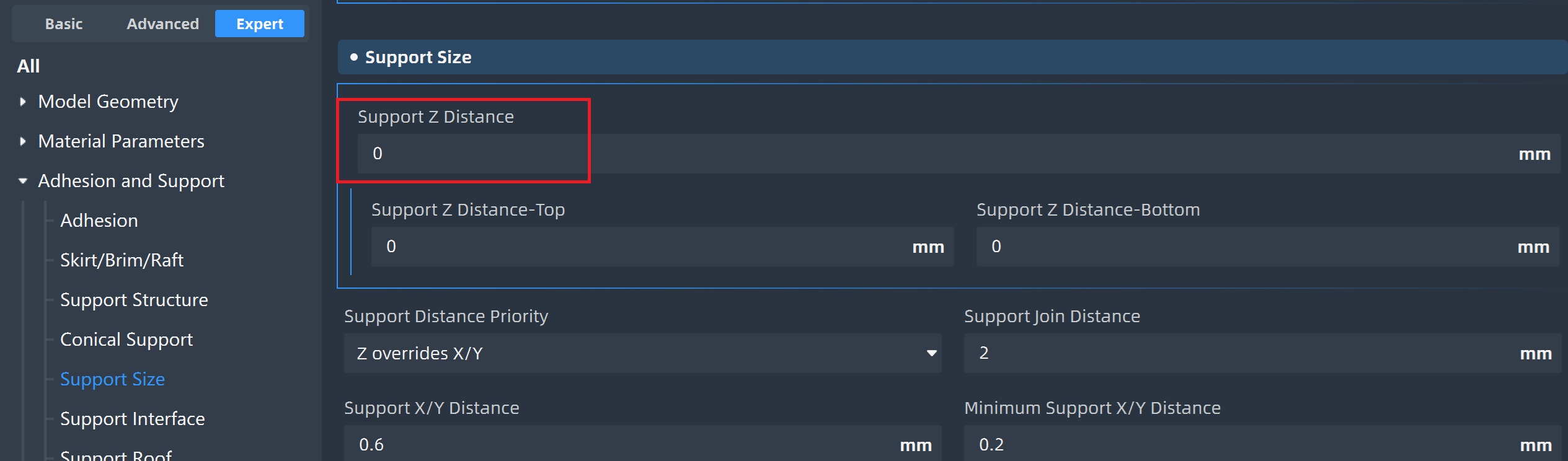

Support Z distance

|

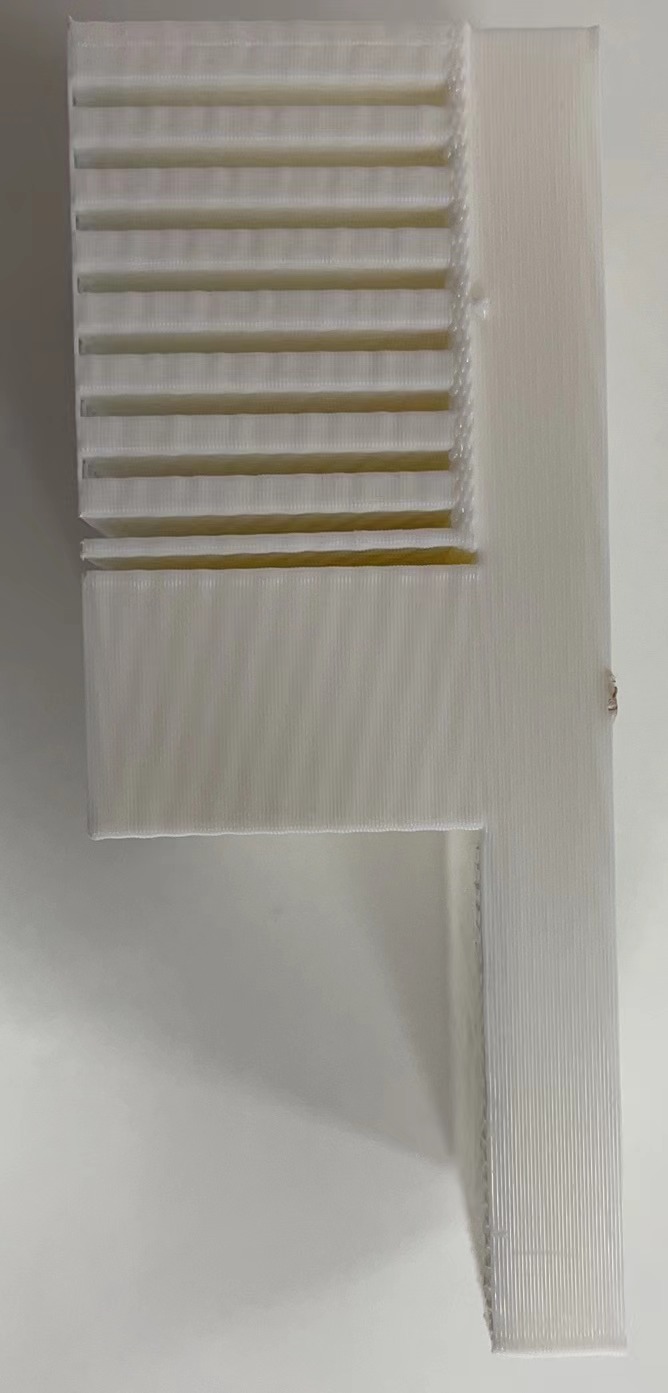

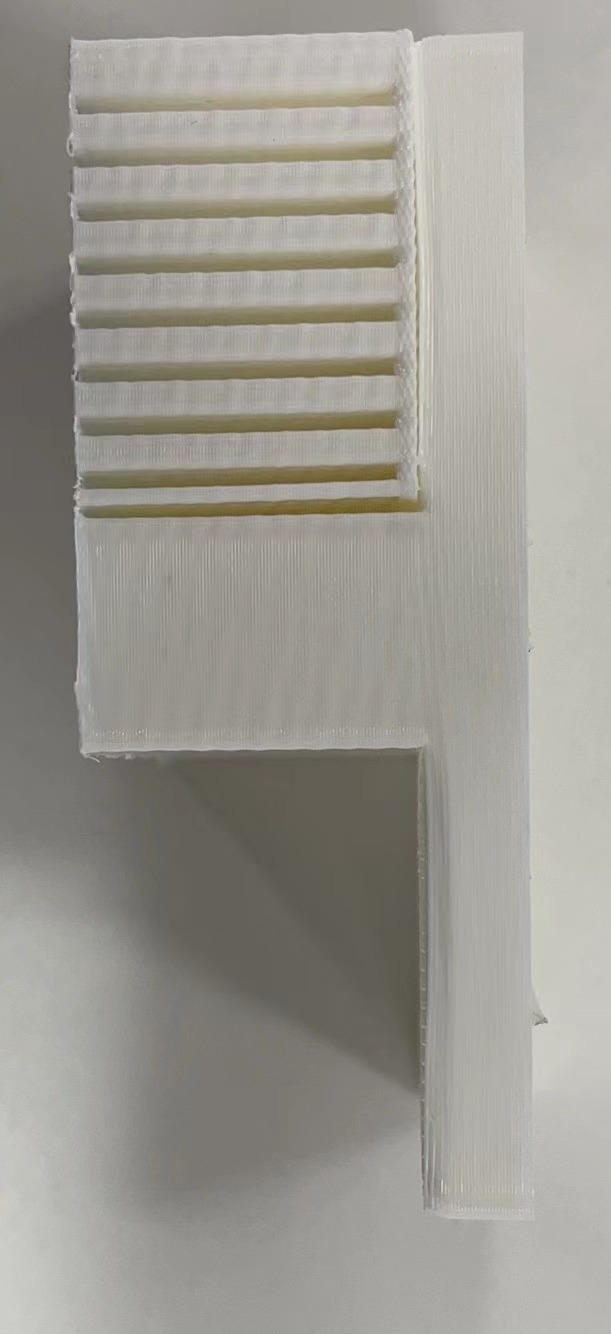

Generally, this setting is used on single nozzle printer or single nozzle mode. Since the model and its supports are printed by the same material, a certain gap between model and supports avoids them not fully bonded with each other, which makes removing supports smoothly during post-processing. The below example was set with an exaggerated and unreasonable value of “support Z distance” in order to show you how it works. As you can see there's a tiny gap in the right figure with 0.2mm set for “support Z distance”, and a hug gap in right figure is for comparison (5mm was set for z support distance). |

|

|

||

|

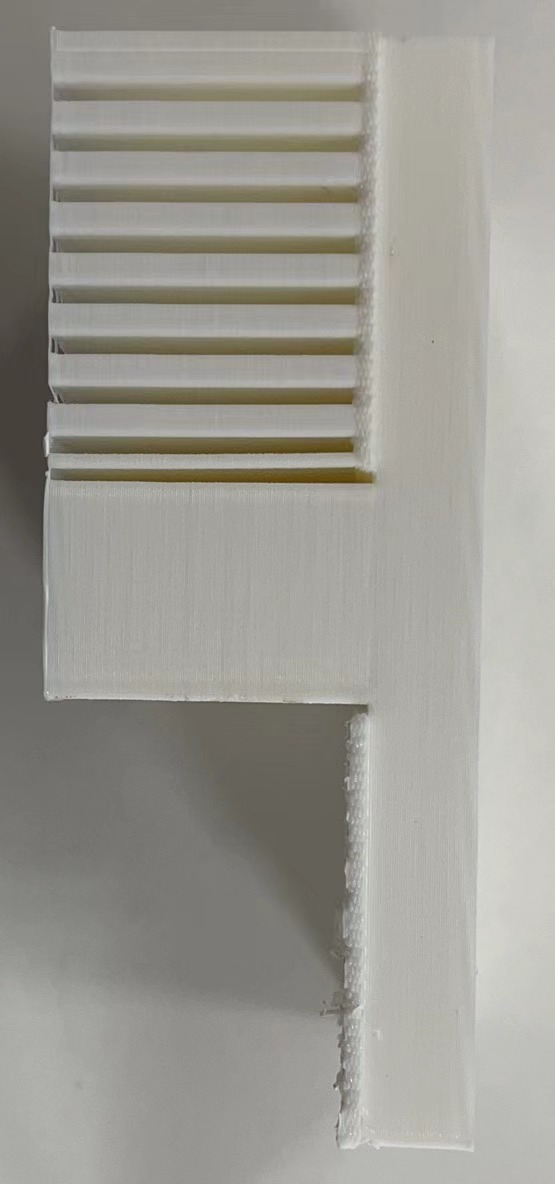

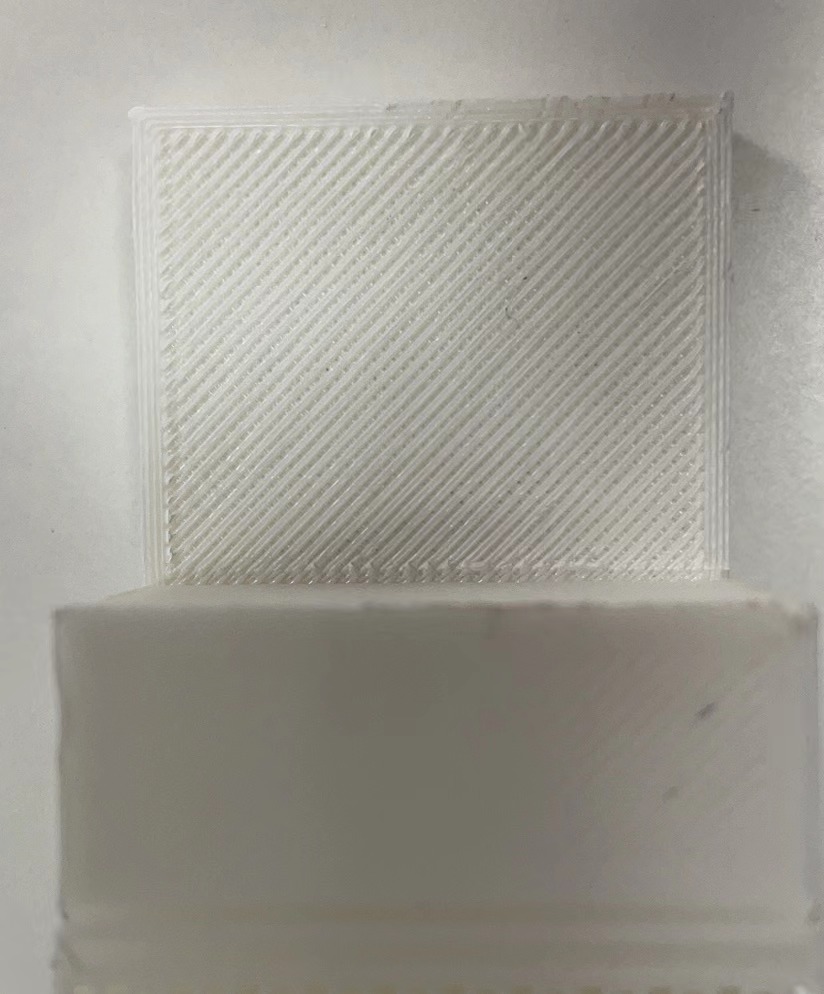

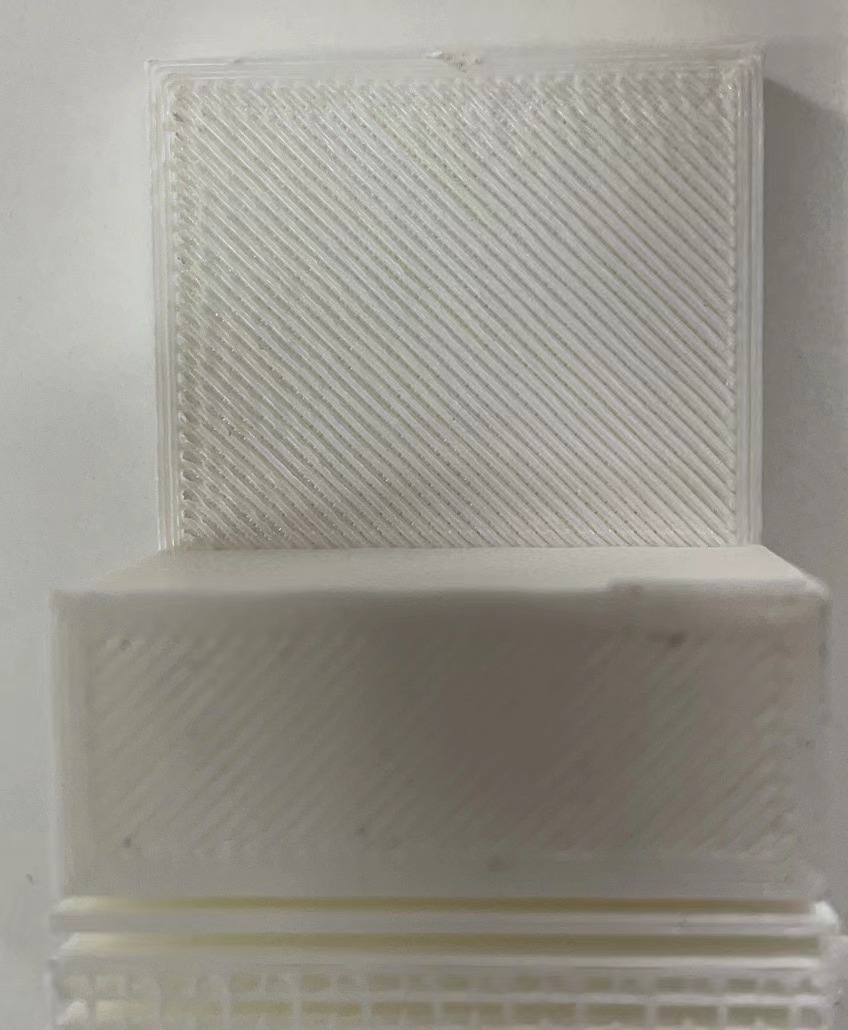

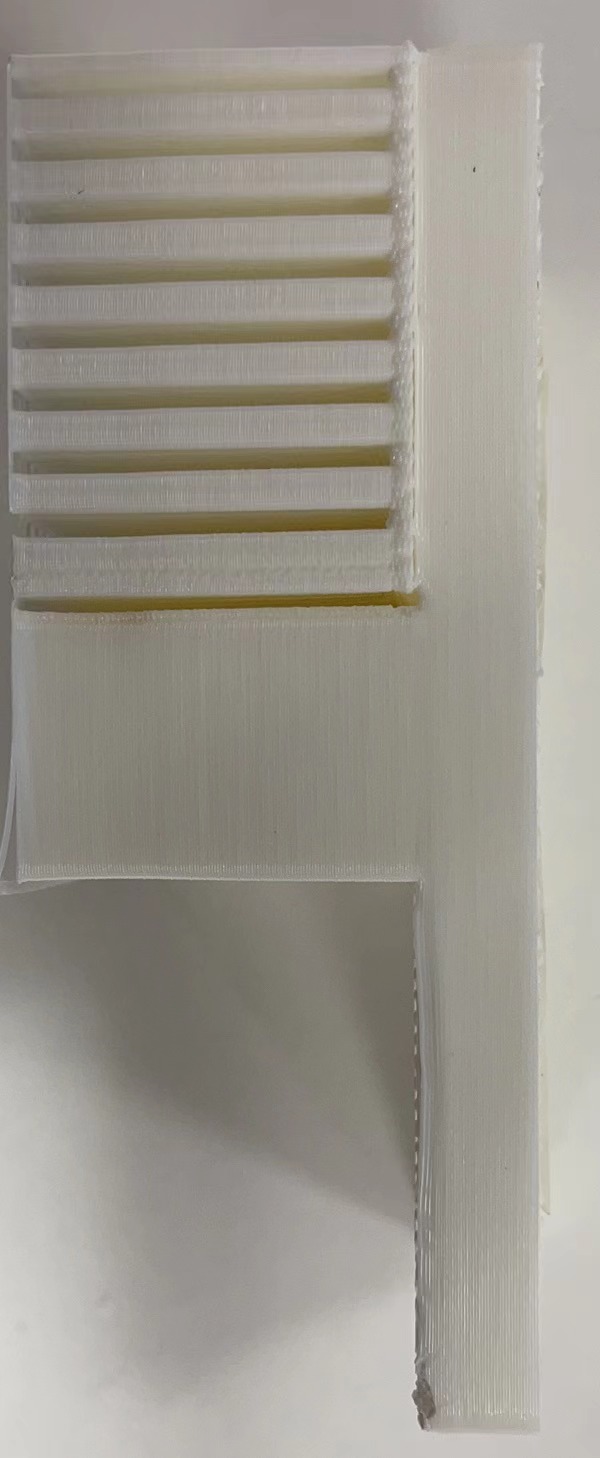

Generally, if “self-supporting” is going to be used, the value of “support Z distance” in default profiles of most filaments equals to the thickness of one layer (0.1mm, 0.15mm, 0.2mm, 0.25mm). However, due to different properties of materials and different slicing settings for example nozzle cooling fan, some materials are more trend to collapse, resulting in poor surface quality of the model surface in contact with the supports. Therefore, trade-off need to be made among surface quality, support effectiveness, difficulty of removing supports and so on. If it's hard to remove supports, “Support Z distance” can be properly increased. If better surface quality is the thing, then decrease “Support Z distance”. For better illustration, here we printed a T-shaped model (printed with ABS) with setting “support Z distance” as 0.15mm (layer height 0.15mm), 0.2mm (layer height 0.2mm), 0.3mm (layer height 0.15mm), and 0.4mm (layer height 0.2mm) Ranking the difficulty of removing supports: 0.15mm - a little hard 0.2mm - reasonable 0.3mm & 0.4mm - easy Ranking surface quality between model and support: 0.15mm>0.2mm>0.3/0.4mm The slightly collapse on the surface is visible when set the value to 0.3/0.4mm (2 layers' height). |

||

|

支撑Z距离

|

The gap - “Support Z distance” |

Surface Quality |

|

Support Z distance - 0.15mm (layer height - 0.15mm)  |

|

|

|

Support Z distance - 0.2mm (layer height - 0.2mm)  |

|

|

|

Support Z distance - 0.3mm (layer height - 0.15mm)  |

|

|

|

Support Z distance - 0.4mm (layer height - 0.2mm)  |

|

|